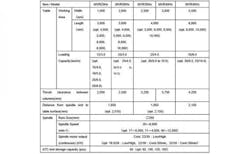

The MVR-Hx Series of Double-Column Machining Centers was developed based on a concept of a machine that is easy to use without thermal displacement for users who pursue high precision and efficiency. It is equipped with thorough thermal countermeasures, such as an internal spindle cooling system that suppresses thermal expansion of the spindle and a main structure that is less susceptible to environmental temperature changes. It can also be used for a wide range of processes for machining that requires high surface quality for all types of materials from light to heavy cutting.

The internal spindle cooling system that cools the spindle from the inside comes as a standard feature. The tooltip position can be stabilized at high speed of 8,000 revolutions per minute, and the step between tools during finish machining is reduced to less than 3.5 ?m.

To eliminate the effects of heat and aging on machining accuracy, there is a thermostabilizer column filled with a temperature control medium, heat insulation measures for the crossrail, optimal placement of scales for positioning each axis, and a spatial error correction function.

Other features include a comprehensive range for the operation panel, an operation support function, Nidec’s IoT platform, and package options available to enable customization.