Thin-Film Mini Components for Next-Gen Smart Devices

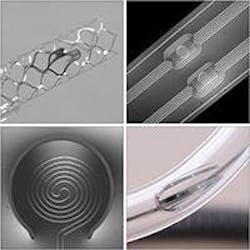

Goodfellow and the German technology company Acquandas GmbH have formed a new partnership to offer micro-patterned, 2D and 2.5D integrated multi-function miniaturized components and coatings with superior performance properties. Smart medical devices and intelligent industrial instrumentation can now be cost-effectively developed and batch-manufactured with significantly higher mechanical properties, increased integrated device functionality and a longer service life.

Materials for thin film miniaturized components

Materials currently available include nitinol (NiTi) and other superelastic or shape memory alloys, bioresorbable alloys, magnetic materials, as well as electrical alloys and insulators.

Applications for a range of industries

- In healthcare this revolutionary technology can be used in the manufacture of next-generation, self-expanding, biocompatible and bioresorbable implant devices and intelligent medical instruments.

- In defense, aerospace, automotive, telecommunications, test equipment and manufacturing automation the technology finds application in shape memory alloy-based electrical actuators for robotic applications, and for the latest microelectromechanical (MEMS) technology to manufacture miniaturized electronic relays, position-sensing linear actuators, micro relays, micro valves and micro pumps. Quantities can range from prototype to high-volume production.