Learn how Ford Motor Company optimized factory-floor tooling production with a 94% lead time reduction by introducing BigRep large-format additive manufacturing.

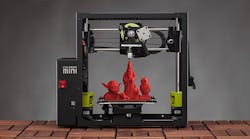

With over 30 years of experience in additive manufacturing, Ford upscaled their Cologne prototyping facilities with two BigRep additive systems. After first acquiring a BigRep ONE, Ford returned their investment with just one application. Following such incredible success, Ford expanded its BigRep ONE’s use and eventually needed more additive manufacturing capacity – leading to their next investment in a BigRep PRO!

Find out about Ford’s highly efficient industrial applications.

Read this large-format additive use case to find out…

- How to reduce factory tooling lead times by 94%.

- How to earn first application ROI with BigRep systems.

- Why leading additive experts choose BigRep printers.

- What the BigRep PRO offers industry leaders like Ford.

Download the case study here: Ford Upscales In-House Tooling with BigRep 3D Printers