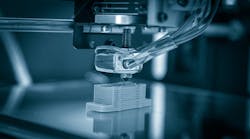

Araqev, a Purdue University-related company, has commercialized a quality-control software for additive manufacturing and 3D printing technologies that any sector could benefit from.

The software offers unique advancements to the 3D printing sector by printing products in only a few design iterations, reducing less scrap and machining time, speeding up production, and improving satisfaction with the final printed part.

"We estimate that the quality-control issue with additive manufacturing can lead to nearly $2 billion in global losses annually based on a model for the production costs of metal additive manufacturing systems that was developed by Baumers, Dickens, Tuck, and Hague in their 2016 paper published in the peer-reviewed journal Technological Forecasting and Social Change," said Arman Sabbaghi, Araqev's CEO and president.

To use the innovative software, customers upload their nominal design files and scanned point cloud data from their printed products. According to Araqev, the algorithms also enable the transfer of knowledge encoded via machine learning models across different materials, printers, and shapes in an additive manufacturing system.

"Our software uses these inputs to fit machine learning models that can simulate shape deviations for future printed products," Sabbaghi said.