Introduction

For decades, the material choices for Selective Laser Sintering (SLS) have mostly been a version of PA11 and PA12. With dozens of commercially available variants, these nylon materials have served the market well and represent the majority of SLS material choices. Now, with the introduction of DuraForm PAx, the industry is provided a unique nylon co-polymer that will be the base material for a new family of SLS materials. PAx is a novel material, with high performance, ease of processing, and a significantly low price point that enables new applications.

With choices, comes the need for more information on which material to use for a given application. This guide has been assembled to assist you in choosing exactly the right material combination for your production parts.

Materials Matter

A benefit of SLS technology is that it offers a wide array of materials that mimic engineering plastics, elastomers, and composites. Rigid materials such as nylon offer strength and durability, and composites can expand functionality further by supporting applications that require increased stiffness, high-temperature resistance, and non-conductivity, among others.

Nylon PA12 is Widely Capable and Easy to Use

PA12 is one of the most commonly used materials in additive manufacturing. It’s a synthetic thermoplastic polymer made from laurolactam monomers that each have 12 carbons, hence the name Nylon polyamide (PA) 12.

Part of the reason for PA12’s popularity is its low melting point. PA12 melts at approximately 348.8°F (176°C), which is among the lowest for nylon polymers. Having a lower melting point is advantageous as it allows parts to cool more gradually, which reduces the likelihood of warping.

PA12 capitalizes on the SLS process and the lack of need for support structures, which are especially hard to remove from small, detailed surfaces. As long as a wall thickness of .08 mm (0.003 in.) is maintained, part design is virtually limitless.

PA12 also offers many other advantages. It’s very strong and resistant to cracking. In fact, given its properties, including a tensile strength is 48MPa, flexural strength 41MPa, and elongation at break at 18%, it’s more likely to bend than break. The material is also very stable over time, absorbs very little moisture, and is chemically resistant. It’s also one of the easier materials to finish with sandblasting, dyes, coatings, and more.

Nylon PA11 Offers Better Performance at a Higher Cost

Polyamide 11, which is more commonly known as Nylon PA11, is a 100% bio-based polymer that has been used in a wide variety of industries for more than 70 years. As additive manufacturing has transitioned from prototyping to serial production, PA11 has seen increasing usage due to its material properties and bio-based materials.

From a chemical perspective, PA11 is very similar to PA12, with only one fewer carbon atom in its polymer chain. However, one less carbon makes a significant difference in how the material responds to additive manufacturing. With its unique crystalline morphology, PA11 offers enhanced mechanical properties, including increased ductility, impact strength, abrasion, and fatigue resistance, especially in colder temperatures. It also provides better isotropic performance, which further enhances strength along the z-axis.

On the downside, PA11 material is typically more expensive than PA12. It also requires a higher temperature, with a melting point of approximately 392°F (200°C). To prevent warping, parts must be cooled more slowly. In addition, PA11 sublimates, creating additional machine stress. To ensure the longevity of the device, more downtime is required for service and cleaning. Together, these factors increase the cost and time involved with making parts.

Combine the Best of Both Worlds

Recently announced, DuraForm Pax Natural is available now. This unique nylon copolymer combines the benefits of PA12 and PA11, offering long-term stability in addition to extreme toughness and durability at an affordable, everyday cost.

DuraForm PAx possesses properties similar to those of injection molded plastics, including high strength, durability, and flexibility. It features high impact resistance with high elongation at break in any direction, including Z. This material also offers a high recyclability rate and cools more quickly than other thermoplastic materials, which creates a cost advantage and improves machine productivity. The PAx is qualified for use with SLS printers from the industry’s leading manufacturers, as well as automated cleaning and post-processing equipment.

Engineered for easy processing and high recyclability, DuraForm PAx is ideal for functional prototypes as well as end-use parts.

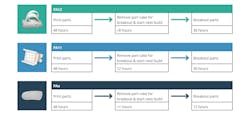

Cost-Efficient and Productive

DuraForm PAx Natural offers a very high recycling ratio, but that’s only part of its economic advantage. It also melts at a lower temperature, cooling parts more quickly, which saves valuable machine time while also reducing maintenance requirements.

Improve End-Use Finish With Vapor Honing

Get Translucency With Vapor Honing

Nylon is naturally off-white in color and is translucent when used on thin surfaces. DuraForm PAx Natural offers some translucency directly off the machine, but the effect can be greatly improved using a process known as vapor honing. It’s a finishing technique that uses low-pressure blasting of media to remove excess material and finely polish part surfaces, and then the part is honed with a vapor. The result is a translucent thermoplastic with properties and a surface finish that compares with injection-molded polypropylene and nylons, making it suitable for applications that require low to mid-temperature fluid flow visualization.

Get Molded Part Aesthetics With Vapor Honing

Some nylon customers express an interest for black versions of the SLS powders they use for a variety of reasons. Many end customers have a color preference for black as it is superior at masking scratches. Additionally, there are instances where black-finished parts eliminate the time and costs associated with painting natural nylon parts. In the case of DuraForm PAx Black, vapor honing further improves the finish of parts by increasing the sheen and making them nearly indistinguishable from molded parts. Adding texture in the design process of parts that will be vapor honed further enhances the finish and enables parts to be used as end-use parts.

Reach Higher Sustainability Levels

Additive manufacturing offers many sustainability benefits. The freedom of design offered by SLS, combined with the mechanical properties of DuraForm PAx, empowers engineers to create optimized parts that are lighter weight and use less material. It also helps with part consolidation and can even help organizations expand digital inventories.

DuraForm PAx offers impressive long-term stability and has been tested for up to eight years indoors and 18 months outdoors. This key advantage creates new application opportunities and furthers sustainability by expanding the service life of finished parts. Further, a low refresh rate ensures the recycling of up to 90% or more of unused powder.

New and Improved Applications

Use for Tough and Flexible Snap-Fit Joints and Living Hinges

Snap-fit joints simplify the process of assembling parts by eliminating the need for fasteners and tools. Typically, they are small protrusions resembling a hook, stud or bead which are deflected, or snapped into place upon assembly.

A living hinge is a thin flexible bridge made from the same material as the two rigid pieces it connects. They are most frequently injection molded and made with polyethylene or polypropylene. Living hinges are inexpensive to incorporate and typically experience low friction and wear making them useful for many applications ranging from defense, military and medical, to consumer products and packaging.

DuraForm PAx’s mechanical properties make it a very effective choice for 3D-printed living hinges and snap-fit joints. The strength and durability of the material resist fatigue and maintains part integrity, while the high elongation at break enables hinges and snaps that are highly flexible.

Ultimate Everyday Material

While dedicated facilities usually focus on internal customers with common needs, commercial 3D printing service bureaus work with clients whose applications span many markets, industries, and use cases. Those that provide SLS additive manufacturing technology typically offer a portfolio of materials but promote one or two for multipurpose use. Material changeovers add expense, and unless there is a specialty need, customers will typically opt for the provider’s “house” material.

DuraForm PAx was designed as an everyday, multipurpose material. Service bureaus offering SLS that adopt it as their material of choice can reduce cost through higher recyclability and faster cooling, while simultaneously increasing machine availability and reducing downtime, creating new opportunities for revenue and profit.

Expand Medical Equipment Opportunities

When it comes to developing and commercializing medical devices, SLS is one of the most frequently used additive manufacturing technologies. Parts are often complex and require strength, durability, and flexibility.

Many different types of medical devices are currently manufactured using SLS. Physicians train and plan for complex procedures with medical models. Surgical guides and instruments improve patient outcomes by allowing doctors to operate with greater precision and less table time. Specialized 3D printed accessories and attachments allow clinicians to expand their use of expensive medical equipment and clinical feedback provides manufacturers with opportunities for continuous improvement, including part simplification and consolidation, lightweighting, and more.

DuraForm PAx can support many of these applications. As mentioned above it is highly isotropic, enabling many applications that require handling of gasses and fluids. It has also passed testing for biocompatibility (ISO 10993-5, Biological evaluation of medical devices - Part 5: Tests for in vitro cytotoxicity) and has been tested (ASTM D543) for surface contact and prolonged compatibility with many common chemicals, including bleach, hydrogen peroxide, alcohol and more.

Enable new automotive applications

The automotive industry also makes extensive use of additive manufacturing technology. For many years it was used solely for prototyping, but it has also been uSed for fixtures, jigs, tooling, and more recently, serial production of finished parts. Plastics make up as much as 50% of the volume of new vehicles but contribute less than 10% of the weight. OEMs and their suppliers are leveraging the unique benefits of SLS to develop and improve existing parts, as well as create new designs that offer better performance and even lighter weight.

As mentioned earlier, DuraForm PAx can be a great choice for fluid applications. In the automotive environment, it has been tested with a variety of commonly used fluids. DuraForm PAx Natural with vapor honing can be used to design, test, and produce translucent reservoirs in less time at a lower cost.

Beyond fluid handling, DuraForm PAx has many other uses within the automotive sector. It offers the strength and durability needed for many applications, including ducting, housings, and enclosures. It can also be used to create jigs and fixtures, in addition to general prototyping.

Stronger, More Flexible Orthotics

Orthopedists and podiatrists around the globe are beginning to consider the benefits of 3D-printed orthotics. As described above, SLS additive manufacturing enables design freedom and the ability to create complex structures. But it also offers many other advantages, including:

- A completely digital workflow

- A streamlined product development process where all iterations, from initial models and prototypes, to finished parts are manufactured using the same technology

- Cost effectiveness, especially with short runs

- Speed-to-market

- Customization and personalization

With recent improvements in 3D scanning, it is now easier than ever for medical professionals to capture a digital rendering of patient body parts. Powerful software allows them to quickly design orthotics and submit orders for production. 3D printing allows them to manufacture high-quality, customized devices with great accuracy and repeatability, on demand.

The new DuraForm PAx is the ideal material for producing orthotics. It delivers a smooth surface finish that users expect from a consumer-oriented product. The mechanical properties of the PAx provide the strength and flexibility needed for orthotics, and long-term stability of the material ensures the devices can perform as expected for many years. In addition, the material offers many sustainability benefits and is cost-effective for manufacturing orthotics at scale.

Why SLS?

With SLS, thin layers of polymer powder are dispersed on a build plate and then a computer-controlled laser traces the part surfaces. Then the thin layers are scanned and fused together at high temperature until the part is complete.

Using a laser to fuse powder delivers excellent layer adhesion, and as a result, parts manufactured using SLS possess isotropic mechanical properties. This along with a wide variety of materials, allows engineers to design durable structures that offer superior strength, stiffness, and elongation.

SLS also offers another important benefit. Because the unsintered powder remains in the bed, it provides support, surrounding and stabilizing the parts as they are produced. As a result, SLS is highly effective at producing objects with complex geometries, which enables greater design freedom. Further, it allows for the “nesting” of many parts within a build area and reduces the potential for damage during post-processing. With other additive manufacturing technologies, parts must be carefully removed from their supports. SLS parts can be pulled directly from the powder bed, and after a quick cleaning, are ready for use.