As far as synthetic lubricants go, polyalkylene glycol (PAG) fluid is an OEM's best friend. And it's a friend of the environment, too.

"PAGs are eco-friendly and sustainable because they last longer than all other types of lubricants," says Jim Girard, vice president and chief marketing officer at Lubriplate Lubricants.

These synthetic fluids, he says, reduce friction, wear, abrasion, and thermal build-up, and can also be water soluble.

"If you get longer life, you have less waste oil disposal and better life on your equipment," Girard explains, adding that some PAGs are also bio-degradable. The key to longer life is in the fluid's ability to resist oxidation.

"PAGs offer the lowest co-efficient of friction over any other type of synthetic fluid or mineral based fluid," says Girard.

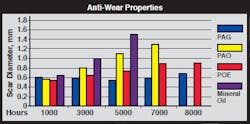

When using a PAG lubricant for 8,000 hours, which equals 11 months of continuous operation, a gear may incur a wear scar diameter of only 0.6 mm.

Anti-wear Properties of PAG's vs Other Lubricants

source: Lubriplate

Lubriplate, which has been around since 1870, the same year John D. Rockefeller founded Standard Oil, predominantly supplies its PGO Series Advanced PAGs to OEMS for use in helical, bevel helical, planetary, and worm gear reducers. According to Lubriplate, their PAGs can reduce energy consumption by 7% in worm gear units.

"Worm gears have a lot of torque and pressure on them," Girard says. "You need a lubricant that can withstand that. Gearboxes create a lot of high operating heat."

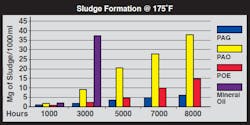

Another benefit of PAGs is that sludge, varnish and gum deposits aren't byproducts. Again using 8,000 hours of runtime, PAGs may form 6 mg of sludge per 1,000 ml, while a Poly-alpha-olefin (PAO) more than six times that amount.

Sludge Formation of PAG's vs Other Lubricants

source: Lubriplate

First used by the U.S. Navy as a fire-resistant hydraulic fluid during World War II, PAGs soon found their way into the commercial market, where they have been gaining traction for their ability increase the life of machinery, primarily in compressors, gear reducers, and hydraulic systems.

photo credit: wikipedia.org U.S.S. Missouri during World War II

When a PAG's amount of oxyethylene is 50 to 75%, the PAG is then water soluble at ambient temperatures. This vastly increases the versatility of the lubricant in gearboxes. Gearboxes frequently come in contact with water, for example, from washdowns," Girard says. "When water gets inside a gearbox, it wreaks havoc on the gear oil."

Because the PGO Series is water soluble, performance doesn't deteriorate if water enters the gearbox.

Lubriplate's PGO Series PAG

Lubriplate also has a PGO-FGL Series for gears in food manufacturing. The NSF H1 Registered PAG is made with a high performance food grade additive package, and provides protection against metal ware and corrosion.

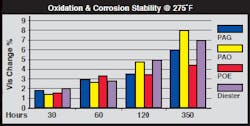

Oxidation Properties of PAG's vs Other Lubricants

source: Lubriplate

The EPA has approved PAGs as an Environmentally Acceptable Lubricant (EAL), because of its water solubility, non-toxicity, and non-sheening properties. Typical oil slicks can cover a wetland ecosystem's surface, putting animals such as otters and beavers at risk.

The most common visual that springs to mind is the Exxon (a progeny of Standard Oil) spill in 1989 in Alaska. A 2010 study reports that up to one and ½ times that amount -- 36.9 to 61 million liters of lubrication fluid -- leaks into marine ports annually.

So, worldwide adoption of PAGs in more applications could do a lot more than extend a gear's life, but the Earth's as well.

And for Lubriplate, which is 146 years old and counting, that's a top priority, Girard says.

"The way civilization is evolving, businesses have no choice but to consider products' effect on the environment. It makes good sense to develop eco products. That's what consumers want."