Biding Time: Bearing Company Helps Bezos with 10,000-Year Time Project

Over the years, Boca Bearings has worked on projects ranging from design engineering, to automation/robotics, to biomedical, to recreation, to food processing, to water treatment and more. And of particularly intriguing note is that the company is currently is providing the very bearings being used in the Jeff Bezos-backed Clock of the Long Now, a mechanical timekeeping system that will tick for 10,000 years, ticking at most once a year. There is also a century hand, and if you can wait a mere 921 years, four months, and 25 days, you'll witness the a cuckoo bird pop out to ring in the millennium. The project was started by mathematician Danny Hillis

Currently being constructed in West Texas in a 500-foot vertical tunnel, stand 200 feet tall and derive power from the earth’s thermal cycles. Anyone will be be able to visit if they can make the several hour drive and precarious hike.

We recently chatted with company president Jason Flanzbaum for some inside info on his own background, Boca Bearings in general, and the significant role it is playing in conjunction with the 10K Clock.

NED: What is the 10,000 Year Clock?

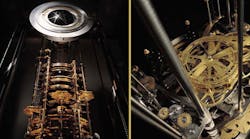

Jason Flanzbaum: The 10,000 Year Clock is a mechanical timekeeping system currently under construction that is designed to run for nearly 10,000 years under its own power. The clock will be built into a mountain in West Texas and display the position of the stars and planets, as well as the date. Given the intended design life of the clock, this is the farthest forward-reaching engineering project currently in progress.

NED: How did Boca Bearings get involved with the 10,000 Year Clock project?

JF: We got involved in the 10,000 Year Clock project upon learning that the Long Now Foundation needed some very unique ceramic bearings to complete the Clock. Testing Boca Bearings’ full-range bearings revealed that ours were the only bearings that could do 350 million cycles without lubrication, with high corrosion resistance and unparalleled working life and high efficiency. Since then, we and the Long Now Foundation have been productive partners!

NED: What were the bearing challenges of this particular application and how did Boca meet these challenges?

JF: The bearing challenges consisted of defeating different factors such as corrosion, wear, lubrication, long-term performance and efficiency. We met these challenges by introducing its ceramic components that are dry running Boca Zirconia Oxide Full Ceramic Radial Bearings—which provide high resistance to wear and corrosion and do not need lubrication to perform well.

And today, nearly every component of this complex system depends on Boca’s ceramic bearings. From large pinion gears and winding differentials of the main power system, to the bell-trigger mechanisms of the chime generator, highly durable bearings are the heart of the Clock. Primarily constructed with three materials—316 stainless steel, titanium and certain ceramics—nearly all the ceramic components are dry running and corrosion resistant, providing consistent and long-term performance.

NED: Can the bearings last the duration of the project? How do you even test something like this?

JF: Yes, the bearings can last the duration of the project. To test them, we developed several cycle-testing setups to simulate the working life that the gears, springs and bearings will experience for 10,000 years. The Long Now Foundation decided to use ceramic options because during the cycle testing only full ceramic bearings performed within the tolerance for the working life of the Clock. In addition, this option is the only one that does not require added lubrication—which is a must for a system that is going to run unattended for several decades. We have tested bearings through 350 million cycles with positive results that exceeded our expectations.

NED: Have you been on-site of the project?

JF: Boca Bearings sent a production crew down to Texas to talk to the people working on the 10,000 Year Clock, and we created a great video telling the story of the project, its mission and our role in this amazing project.

NED: Why is it so important today to think long-term about our manufacturing and engineering future?

JF: Technology is moving faster than ever, and yet we know that the products we are producing today are the building blocks of the future. That said, we also see the damage that can be done by taking a short-sighted perspective on various manufacturing processes and systems. So while we certainly won’t do anything to slow progress, we are always cognizant of the future to know where we’re headed and how exactly we’re getting there.

NED: Why is it so important for your organization to participate in projects like this?

JF: Participating in a project like this allows us to develop long-term thinking. We are all here for a certain period of time, and we have to make it count. What are we going to pass on to future generations? The idea here is to inspire people and try to change the way they think about time; try to make them take advantage of it. Once in a while, we should take a moment to reflect about what we are doing in a long-term basis and ask ourselves, are we going in the right direction?

And the 10,000 Year Clock is a pretty proud message we like to share whenever people ask about the shelf life of ceramic bearings and how they hold up over time. Is there any greater example of durability than a 10,000-year project? It’s a fantastic illustration of modern ceramic bearing technology.

NED: What were some of the biggest surprises or life lessons your organization learned from this project?

JF: One of the biggest—if not surprises, but confirmations—for us has been just how long these bearings are able to last. In working with the 10,000 Year Clock, and witnessing the development of testing rigs that put millions of rotations on the bearings, it was amazing to see the thought and detail that have gone into this project. During our time working on this project, I had a son; and so thinking about his future, and his son’s future down the line, 10,000 years was an incredible moment that I still think about today.

NED: At what stage of development is the Clock?

JF: The full-scale 10,000 Year Clock is now under construction, with the mountain currently containing a bored cylinder and a carved-out spiral staircase cut into its walls. Many of the Clock's parts have been built and are in varied stages of assembly, testing and shipping to Texas. Rest assured the process continues at a feverish pace; more to come on official timelines.

NED: Anything else unique about this project that readers might be interested about which to learn more?

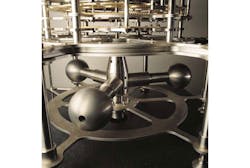

JF: One interesting fact is that visitors can add energy to the Clock’s storage system by winding up a capstan, in which a series of differentials turn three large pinion gears. These gears mesh with the three arms of the rack segments, which in turn connect the power system to the counterweight. The capstan is fully built, tested and has been shipped to Texas. Once installed, the more people who show up and wind the capstan, the longer the flock can run; so it potentially could run beyond 10,000 years if maintained!