The development and practical application of electroplated zinc-nickel alloy coatings began during the 1980s, and its acceptance and use have grown slowly but consistently ever since. So Zn-Ni coatings are not as widely used as other traditional protective coatings. This is unfortunate and likely due to the fact the process and the benefits it brings are subject to some misconceptions. The truth is, Zn-Ni coatings offer manufacturers valuable options for meeting ever-increasing regulatory, warranty, and performance requirements that affect their products.

New regulations, for example, are encouraging more auto, truck, and small-engine designers to consider it more seriously. It has also been adopted widely by the aerospace industry and is increasingly being used to protect heavy construction and agricultural equipment, as well as components and devices of all kinds that are exposed to environments that lead to excessive corrosion.

Here’s a look at the nature and benefits of Zn-Ni electroplated coatings, and how they benefit real-world applications:

Benefits of Zn-Ni Coatings

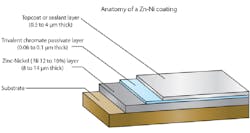

Zn-Ni alloy coatings (usually composed of approximately 85% zinc and 15% nickel) are electroplated on carbon steel as a protective coating in a process similar to the way zinc coatings are applied. Zn-Ni coatings typically consist of 8 to 14 mm layer of 12 to 16% nickel alloy next to the substrate topped by a 0.06 to 0.15 mm trivalent passivate layer and a 0.5 to 4.0 mm top coat layer.

There the similarities end: Zn-Ni alloy coating significantly exceeds the protection offered by other coatings in three main areas:

• It offers greater corrosion protection.

• It provides more wear resistance in moving parts

• It limits thermal stress to parts subjected to higher operating temperatures.

sealant on top.

In the electroplating process, Zn-Ni coatings also have good throwing power (the ability to plate in recessed areas on parts with a complex shapes) to better coat blind holes and recessed areas.

Here is a brief summary of its benefits:

Corrosion protection: As a true alloy, Zn-Ni coatings are proven to provide two to three times more corrosion-resistant protection than zinc-only coatings. Furthermore, the crystal structures of Zn-Ni deposits are a uniform single structure that creates a thin, consistent protective layer across the entire surface being coated. Zn–Ni coatings provide corrosion resistance equal to or greater than cadmium coatings and they eliminate the risk of carcinogenic exposure that creates a concern for people working with cadmium-coated components.

Aluminum substrate parts have become more popular for automotive components. Due to aluminum’s differing electro-potential when in contact with steel, aluminum parts are subject to attack by galvanic corrosion. Fortunately, accelerated corrosion tests show that Zn-Ni coating also protects against this galvanic-induced corrosion.

Increased wear resistance: A hard, thin-film Zn-Ni coating has a consistently smooth finish that increases wear resistance both through its hardness and by producing a surface that virtually eliminates irregularities, reducing both friction and opportunities for abrasion. On the Vickers hardness scale, parts coated with Zn-Ni reach 450, compared to less than 150 for zinc-coated parts.

Thermal stress relief: Zn-Ni coatings provide added protection against thermal stress. As a result of regulatory requirements, today’s automotive engines, for example, are smaller and tend to run at higher operating temperature. This creates thermal stresses on other components within the engine compartment, and Zn-Ni coatings have been found to reduce the effect of that stress. Tests show, for example, that components coated with Zn-Ni retain their corrosion resistance despite exposure to thermal stresses in temperatures up to 200°C, as opposed to zinc-coated parts, which resist thermal stresses up to only 120°C without losing corrosion resistance.