The room is pitch black. You just climbed into bed, and before your heavy eye lids shut for the last time of the day, you remember, "I forgot to charge my phone!"

So you get up, fumble around for the wire that fell behind the nightstand, and then clumsily struggle to plug the connector in the right way, like you're a chimp putting together an IKEA coffee table with a greasy Allen wrench.

This exercise in frustration even affects the most intelligent of humans, such as MIT professor Marin Soljačić. Like the rest of us, the Croatian-born physicist and electrical engineer wanted to be able to set his phone on the nightstand and wake up the next morning with it fully charged.

So the professor and his research team went to work, and in 2007, produced a prototype that used highly coupled self-resonant coils to wirelessly transmit power to a light bulb over a two meter distance. Soljačić founded WiTricity Corp. to commercialize the tech the following year, and in 2014 released a charging pad for smartphones.

Soljačić's team wasn't the first to demonstrate wireless energy transfer; Nikola Tesla had them beat by more than a century with the Tesla Coil. However, unlike with lightning-projecting Tesla coils, you can safely pass between WiTricity’s fields, because they rely on magnetic resonance.

Image: WiTricity

"Magnetic fields are very safe for people," explains David Schatz, WiTricity’s vice president of business development. "They interact very weakly with living things, unlike electric fields."

When in range, a capture resonator that is tuned to the right frequency will magnetically couple to the source, and convert magnetic energy back into electrical current. WiTricity’s patented technology enables such systems to work over distance and at very high efficiency, compared to traditional inductive energy transfer.

The range is anywhere from a few to tens of centimeters, maintaining power level efficiencies, and has been demonstrated to work across a room.

"It's like a harmless version of alternating current that can travel without a wire," says Schatz, who does mention that dropping keys or loose change directly onto the resonator in industrial setting could heat them up, although for low power consumer uses, this isn’t an issue. For higher power systems, safety sensors detect the presence of metal objects and shut down the system before the objects can heat up and be a safety hazard. In the industry, this is call “foreign object detection," or FOD.

You'd think using magnetic fields to transfer energy would increase your overall electric costs, but WiTricity reports its system has demonstrated 93% efficiency end-to-end, while a conventional wired charging system is on average 80-95% efficient.

Check out WiTricity's WiT-3300 Charging System Specs Here.

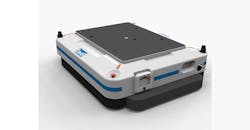

In early November, Daihen Corp., a Japanese industrial equipment manufacturer, announced it would begin shipping systems based on WiTricity’s patented technology, with WiTricity’s technology enabling a wireless power transfer system, D-Broad. The D-Broad Core is currently powering Daihen's AGVs, called AI Transfer Robots, and next spring, the system will be available to OEMs.

With this system strategically placed on the factory floor at frequent stopping points, AGVs will truly be able to operate 24/7, meaning you need fewer AGVs in your fleet.

Instead of taking an AGV offline to charge for eight hours, it can instead power snack on the go, filling up on energy while it loads or unloads its cargo. WiTricity calls this "opportunity charging."

In theory, you could already do this with docking stations and conductively charged AGVs, but to illustrate why this wouldn't work, you should recall what a pain it is connect your phone.

"With mobile phones, the most likely component to fail is the connector," Schatz says. "The pin gets dirty, or it gets bent. The same happens in factories."

Those AGVs are little material-handling miracles, but they're still little more than glorified skateboards in the brains department.

"These vehicles move around with an accuracy of a few inches," Schatz says. "Imagine the force exerted on the connectors if it's misaligned by an inch. The connectors are designed to be somewhat compliant, but every time you make a connection, you cause wear and fatigue."

So docking frequently for opportunity charging would decrease the life of the connectors and require more maintenance/repair man hours.

Image: Daihen

Saving on maintenance is nice, but what a company can gain from having an insomniac army of AGVs is the real dream come true for plant managers.

Consider how much you would save by cutting your fleet from five to three AGVs, which according to NDC Automation, would cost $12,000/month and $19,200/month, respectively, for a five-year year lease. That's a savings of $86,400/ year.

And if you have a fancy new machine vision AGV that can cost upwards of $100,000?

"The cost of a wireless charging station is easily one-tenth to one-twentieth- of that," Schatz says.

While this technology presents exciting productivity and cost advantages now, just wait until the technology expands into the electric car market. This could drive the cost down to under $1,000 per system, Schatz says.

WiTricity says all major car companies have an active wireless charging program, and two German automakers could have the magnetic resonator system installed in their cars in a year.

The effects extend beyond consumer convenience and industrial opportunity charging.

Image: WiTricity

The applications seem infinite, extending to virtually anything that uses a Lithium Ion battery, from consumer electronics to automation equipment to medical implants.

And all this constant charging will extend the life of the batteries themselves.

"Lithium Ion battery packs have a certain number of charging cycles they can sustain before they lose ability to hold charge," Schatz says. "If all you ever did was drain the battery from 100% to 50%, they would last a lot longer. Draining to dead strains the battery. Extending the life of battery is good for the environment, keeping them out of landfills and ultimately reduces the cost of batteries."