Miniature Spectroscopy Sensor Project Has Big Industrial Ambitions

New miniaturized spectroscopy sensor technology developed by a European consortium could do for chemical sensing what camera phones have done for visual imaging.

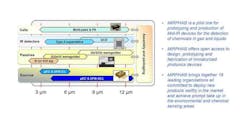

Developed by the MIRPHAB project, this sensor, which could be fitted on a drone, detects the specific frequencies of liquids or gases when they interact with light. The project's goal is to facilitate faster prototyping of viable Mid-IR sensors that could be commercialized by 2020 or earlier.

MIRPHAB stands for ‘Mid-Infrared photonics devices fabrication for chemical sensing and spectroscopic applications.’ That’s quite a big name, though it dreams small.

"We want to shrink current [spectroscopy] technology down to the size of a mobile phone," MIRPHAB coordinator Sergio Nicoletti says.

Its scanning range is up to 30 meters, and has a detection rate of 1,200/hr, or one every three seconds.

Because of the compact size and long range, these sensors attached to drones could be the 21st century version of a canary in the coal mine. An industrial chemical company may use it to sense methane leaks, or for use in hot and/or hazardous areas unsafe for humans carrying traditional portable spectrometers.

“You can monitor specific chemicals in a process to optimize yield and to reduce emissions,” says Nicoletti, adding that MIRPHAB has the infrastructure to fabricate, assemble, and represent the full supply chain.

Because of the innovations in spectroscopy and streamlined supply chain, Nicoletti is confident this could reshape multiple industries where chemical sensing is vital.

“We are making the next generation of sensors that are compact, low cost, low on power consumption and capable of real-time detection where the speed and sensibility is unrivaled,” the director says.

The project's objectives include:

- Becoming a pilot line for prototyping and production of Mid-IR devices for the detection of chemicals in gas and liquids;

- Offering open access to design, prototyping and fabrication of miniaturized photonics devices;

- Fostering the emergence a new market segments for optical sensing by reducing the investment cost to access innovative MIR solutions

In the industrial world, the applications can range from sensing of hydrocarbons (methane, propane, butane, etc.) to monitoring emissions (Nitrous Oxide, Nitric Oxide, Sulfur Dioxide, etc.).

“Our technology will bring into play miniaturization to allow a number of different applications that are not possible today,” Nicoletti says. “It can even be applied to detect very early diseases by monitoring specific chemicals.”

The sensor monitors in the MIR wavelength band (3/12 μm), also called fingerprint region.

“In this region, the signatures are most distinct,” Nicoletti explains. “The overlap between the signatures is lower and the abundance of absorption features makes identification of different components is easier. These are the two critical factors that allow for better sensitivity.”

MIRPHAB is coordinated by CEA-Leti, France, and has received more than €13 million in funding from the European Community and an additional €2 million from the Swiss Government.

Access to the technology is open to companies worldwide, although because it is a European project, those companies may receive a grant support from MIRPHAB to develop their own sensors within the pilot line.

“Any European company with a business on analytical sensing can apply for support,” says Jose Pozo, director of technology and innovation at the European Photonics Industry Consortium. “They will receive matching funding to cover the prototyping costs of the MID-IR sensing system of up to €230K. Such a system will be integrated from mature components from our extended library, including laser sources, detectors and micro-optics. Furthermore, the related services to prototyping also include micro assembly and standard reliability studies.”

For more information, please visit: http://www.mirphab.eu/