Powerful New Tool Mixes Safety, Protection, and User-First Innovation

Apex bits and sockets are a basic staple in the manufacturing toolbox on just about any assembly line, particularly in the automotive world.

The company's proprietary recipe for precision drive tools has made their products ubiquitous in the market. They are attached to the power tools in the hands of operators around the world, ready to piece together critical components on some of the most sensitive assemblies hitting the roads.

Over the last few years, however, a new piece of equipment has joined the Apex product family, adding a new level of productivity and comfort to the set.

Part safety device, part workpiece protector, the bright orange u-Guard covered drive tools have hit the market in a big way, offering applications and benefits on the job that even Apex didn't expect.

Born directly from user feedback and requests, the story of the free spinning u-Guard design offers a vital lesson on the value of listening to the customer and some key insights on the innovation process at Apex that made it possible.

Recently, we met up with Vipul Agarwal — Global Product Manager, Industrial Fastening Tools at Apex Tool Group — to learn more about it.

NED: Could you tell me how the idea for u-Guard came about at Apex?

AGARWAL: Our customers were telling us that their work pieces were getting damaged because of the contact between the metal drive tool and the work surface.

Imagine a vehicle or an appliance coming through the assembly line and the operator perhaps leaves the fastening power tool for a second to do something else and, boom, it scratches or dents the workpiece.

The general damage or marring or denting on the assembly line of these expensive parts happens frequently, and the cost for the plant to take care of these damages can be significant.

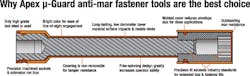

Apex solved this growing problem faced by our customers by engineering a solution that evolved into a line of covered fastener drive tools, that is, sockets, bit holders, and universal wrenches, to prevent the in-system damage occurring on the assembly lines during fastening. That was the beginning of our u-Guard line.

NED: U-Guard is also considered a safety device, though. How does that element fit in?

AGARWAL: That's true. Gradually, it has evolved into not only a tool to keep the work pieces safe—not only for anti-marring or anti-scratching—but it has become a safety device also.

The reason for that is, on the assembly line, when an operator is using gloves, there is a potential for injury if the operator's gloves or even hair get caught by rotating tools while driving a fastener.

Many assembly plants have adopted policies recently to minimize injuries by using covered drive tools, which is what u-Guard is. These covers allow the drive tool to spin freely inside of them, in order to significantly reduce or, in most cases, eliminate contact from the rotating tool during a fastening operation performed with gloves.

Let me explain. So, take a socket, you put the cover on the socket to that socket can now spin freely inside the cover, but when the operator holds the tools, from the outside, their fingers do not feel that rotation anymore, because it is free spinning.

Leading automotive companies have come out with strong recommendations to their plants that they need to offer covered tools on the line because of safety, marring, and ergonomic conditions.

That's where u-Guard comes into play. It offers safety benefits, ergonomic benefits, and anti-marring benefits.

It's a home run. It's a no-brainer for plants. It brings them multiple benefits.

NED: Were those safety features in the original product, or did you have to go back and modify the design to incorporate them?

AGARWAL: That functionality was already in the original design.

NED: So the users actually discovered that it was a handy safety device?

AGARWAL: Yes. I am glad that it worked out well for our customers. Not only did they get a product that solved their marring issues on the assembly line, but it provided an additional benefit of keeping their operators safe while performing fastening operation. It was icing on the cake!

NED: That's fascinating. Not only the concept for the design but also the secondary functionality of it, came directly from your customers. That means you must have a pretty elaborate communication line with your clients. Could you describe that for me?

AGARWAL: “Customers First” happens to be one of our company’s core values, and we live and breathe it every day here at Apex.

One thing that we really like to do is take care of our customers. Whether it is by creating superior quality standard products that significantly outlast the competition, or by developing unique solutions that will improve their productivity and produce cost savings, Apex will always go the extra mile to keep our customers happy.

The fact that Apex has been THE leading company in bits & sockets for almost 85 years is, I believe, mainly because we listen to our customers and solve their most challenging fastening tool related problems.

NED: How does this work at Apex, exactly?

AGARWAL: It starts with listening – when customers talk, we really listen! We take “voice of customer” very seriously.

There are multiple ways in which we touch our customers. Our sales team is in customer plants every day talking to them about their problems, unmet needs, and how Apex can help them. Our team of dedicated application specialists is available for customers to contact in case they would like to discuss a custom solution for their unique situation. I travel as much as I can to go and see customers to find out what they need and what we can do for them.

I believe that this level of customer support is unheard of in our industry, and we take great pride in our ability to be there for our customers!

Based on working closely with customers, we have created thousands of unique products that have solved their critical problems. Apex has become the trusted name for customers when it comes to superior, innovative fastener drive tool.

NED: The u-Guard is no small fix, though. It's a fully-engineered, complex solution, which must have consumed a lot of R&D dollars, gone through a fairly extensive prototyping process. How does that go? How does it go from comments from the customer to production?

AGARWAL: We believe that Apex manufactures the best industrial grade bits, sockets, and universal wrenches in the world. Our products provide significantly lower total cost of ownership to the customers when compared to most competitors.

It all starts with an “Ideation Funnel” where we put all the potential product ideas. We have a cross-functional team that has regular meetings to discuss the running list of new product development (NPD) ideas and prioritize them. After a detailed market research and analysis, we take the highest priority ideas and proceed to launch them.

This process consists of innovative engineering design and development, creating prototypes to test the product, and, in many cases, performing field trials to validate the design. Only after we confirm that the design offers the superior performance that customers have come to expect from Apex do we go ahead and launch the product. Our advanced manufacturing process, starting with proprietary materials and heat treatment process, results in a durable, consistent product that outperforms competitive products and provides unmatched design and cost benefits to our customers.

NED: So, u-Guard is just one in a long series of products you are developing to answer the real world questions.

AGARWAL: Absolutely. Every year we create hundreds of products to solve our customers’ problems.

We are the leading bits & sockets company in the world. For more than 80 years, manufacturers around the world have relied on Apex to solve their critical fastening problems, and we take that responsibility very seriously.