Long-Lasting Solenoid Pinch Valves Perfect for Disposable Processes

When Bimba Manufacturing acquired Acro Associates, Inc. in 2013, the pneumatic and fluid control leader gained access to three decades worth of pinch valve technology -- and an immediate foothold in the burgeoning biomedical industry.

The full potential of this partnership was realized with the 2014 launch of the Versagrip series of solenoid pinch valves, which can work with tubes ranging from 1.6 to 9.5 mm in diameter and have a 3 million MTBF. They are available for OEMs and custom processes.

A pinch valves work by clamping down on a disposable tube inserted into its slot, allowing for fluid flow control without direct contact. The sterility of the process makes it an obvious choice for medical applications such as with intravenous systems, drug delivery, and dialysis machines.

The system interfaces with one or several of these electrically-controlled valves to create a complex and precise network that actuates in 80 milliseconds.

“It gives the system the ability to control the fluid in a very managed way during the treatment,” says Winston Wong, director of business development for Bimba’s medical division.

You could use pneumatic-operated pinch valves as well, but for medical clinics and hospitals, which often don’t have internal compressors for their devices, solenoid are preferred. The 15-psi valves don’t make as much noise as the 45-90 psi pneumatic valves, either. If you’ve stayed in hospital room for more than three minutes, you understand that the less beeping and clunking, the better.

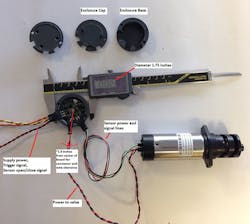

How the Versagrip Solenoid System connects together.

Wong says the Versagrip’s key features set the valve up to be an industry leader. These include the various tube loading shapes for different tube thicknesses and diameters. The standard radius geometry was designed specifically for biological fluids.

“It allows the valve to be 100% effective and gentle on the tubing,” Wong explains. “And it doesn’t shear the biological material, such a blood or plasma, while it’s being processed. You don’t have a harsh pinch that will essentially shear the cells open.”

He says that’s why for applications such as renal dialysis, which acts as an artificial kidney and filters a person’s fluids, this method works extremely well.

According to a 2015 report, 469,000 Americans are currently receiving dialysis.

The valves also run the full gamut of compliance, including ROHS2, CE 60601-1 3rd Ed., UL429, and CSA139.

The 18-month warranty and 3 million cycle MTBF are what Wong seems to be most proud of.

“That’s a standard we believe sets us up a s a leader in performance and reliability,” he says.

The company strived to be completely transparent with the testing methods and how they achieved such a long lifespan.

|

Versagrip Solenoid Pinch Valve Specifications Standard 24VDC x 3A power input

|

“When you try to set up stringent replicate worst case, and provide value, then it becomes very clear what you’re publishing,” Wong says. The MTBF for the Versagrip was based on a “50% duty cycle testing carried out at 20 degrees C ambient using 60-Shore A tubing.”

“I think it’s an added layer of value because a lot of their quality and documentation support requires not only certificates, but they like to know minimum life expectancy,” he continues. “And it allows them to quickly extrapolate how long it would be effective in the overall device.” Each valve, and the PWM control board, all have a microcontroller chip about the size of a pen tip to store cycle use and failure.

The valves are available for food and beverage and chemical processes, and have found a major role in Bayer’s F³ (Flexible, Fast & Future) Factory project. These mini-manufacturing plants are the size of a shipping container and allow large scale production in a mobile and modular environment with a micro-scale footprint. The Bayer Process Equipment Container Unit uses 70 Versagrip solenoid valves.

Bayer's F³ Factory.

About the Author

John Hitch

Editor, Fleet Maintenance

John Hitch, based out of Cleveland, Ohio, is the editor of Fleet Maintenance, a B2B magazine that addresses the service needs for all commercial vehicle makes and models (Classes 1-8), ranging from shop management strategies to the latest tools to enhance uptime.

He previously wrote about equipment and fleet operations and management for FleetOwner, and prior to that, manufacturing and advanced technology for IndustryWeek and New Equipment Digest. He is an award-winning journalist and former sonar technician aboard a nuclear-powered submarine where he served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723).