For Critical Cable Installations, You Get What You Pay For

Cable installations in rugged environments are serious business. In the oil and gas industries in particular, users depend on rugged, explosion-proof systems to keep their operations running and their workers safe no matter what conditions are thrown their way.

In all, the rugged copper wiring snaking through these plants are generally up-to-spec. Specifically in the instrumentation applications, installers often boast low-smoke, non-toxic, halogen and phosphorous free wires that is guaranteed to survive the worst day in the facility.

But this wiring only constitutes about 98% of the total system.

The other 2%—the fittings or cable glands that are the critical junctions between cables and equipment—is often forgotten in this quest for rugged protection.

That omission can be costly, if not unsafe.

"Manufacturers worry a lot about the compliance of their cable systems, but they don't worry about proper termination," explains Raphael Brunner, VP of Operations at Sealcon.

"I would claim 90% of installers ignore or are unaware of more state-of-the-art technologies when it comes to fittings and glands and resort to inferior products," he says. "Many don't know or simply don't care. It's very unfortunate and to the disadvantage of the customer."

"You want to brag that you have this nice car and can handle common road challenges, but when you take your friends out for the first time you blow a tire. You go around a curb, and the tires fall off the rim," he says. "It's the same when you attach a cable: “You get what you pay for."

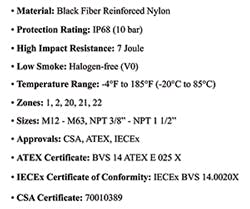

This gap in protection led to the design of a Sealcon's fiber-reinforced nylon strain relief, the ‘BXA’ fitting—built to take on the missing 2% of protection in instrumentation, panels, and lighting fixtures.

The IP68 (10 bar) rated, low-smoke, halogen-free, ATEX / IECEx, Class 1 & Div 2 rated, non-metallic fitting offers a unique solution for electrical cable attachments in hazardous and rugged atmospheres.

Boasting a lightweight, highly impact-resistant design, the fittings were built to help guarantee top-to-bottom electrical protection where users need it the most.

These BXA fittings, Brunner argues, are a critical piece of these installs.

"If you want safety, if you want compliance, if you want to meet customer specs and peace of mind, you need a solution made of higher quality material," he says. "That's not a low cost solution."

Installers opting for cheap solutions, he argues, are exposing not only their clients but themselves to significant risks.

"If you install a cheap, inferior system and something happens, it can damage your reputation in the market," he says. "You can't put a price tag on reputation."

Sealcon's BXA—among many other Ex-e and Ex-d rated cable gland options—offers various alternatives.

"We're not cheap," Brunner notes. "We offer a high-end cable management solution for customers that appreciate the fact that if they spend a few extra dollars here, they can save hundreds of thousands of dollars down the line for repairs and damage control.

"It really comes down to this: You get what you pay for. So pay for the best."

About the Author

Travis Hessman

VP of Content, Endeavor Business Media

Travis Hessman is the VP of Content for Endeavor Business Media. Previously, Travis was the Editor-in-Chief for Industry Week and New Equipment Digest as well as the Group Editorial Director for Endeavor's Manufacturing Group.

He began his career as an intern at IndustryWeek in 2001 and later served as IW's technology and innovation editor. Today, he combines his experience as an educator, a writer, and a journalist to help address some of the most significant challenges in the manufacturing industry, with a particular focus on leadership, training, and the technologies of smart manufacturing.