Of the myriad hazards that an astronaut may face on a spacewalk, drowning is not a problem Houston ever expected.

That’s exactly what NASA’s mission control narrowly avoided in 2013 when Italian astronaut Luca Parmitano’s helmet started to fill up with water globules while on a spacewalk outside of the International Space Station. Only 45 minutes into a six-hour mission, the astronaut’s helmet started taking on water, reaching almost two quarts and entering his nose.

Completely blinded and without communications, Parmitano found his safety tether and felt his way back to the airlock while he was still able to breathe. And all of NASA breathed a collective sigh of relief.

Thankfully, this harrowing spacewalk, detailed by Parmatino himself here, will go down as just another example of how inconceivably cool and collected astronauts are, and how even the most meticulously engineered equipment, such as a spacesuit, can be improved.

NASA traced the leak to a clogged fan pump and altered the flow path, resulting in new complications.

“The changes solved the ‘drowning-the-astronaut’ scenario, but now when the astronauts come out of the spacewalk, they have to carefully dry the suit out to get the water out of the bearings,” says Christopher DellaCorte, senior technologist for tribology and rotating machinery, at NASA Glenn Research Center.

Bearing corrosion is an issue because it can prevent mechanisms, like the suit’s fan pump separator from working properly, which happened last Fall. Though a rusty bearing isn’t a life-threatening problem, it’s not good and needs to be fixed.

It’s a good thing sciencing the s*** out of things is NASA's main motivation, from fictional botanist Mark Whatney on the barren, red terrain of Mars, to DellaCorte, who has worked his entire career within the same austere brick building in an Ohio field.

Bearings, along with virtually all interacting surface properties, have been DellaCorte’s specialty for 30 years, and he believes NASA already has the ideal material to make many bearing problems obsolete: NiTiNOL 60, a non-corrosive, shockproof alloy comprising 60% Nickel and 40% Titanium. Rust is not a problem because it’s non-ferrous.

Bearings using this material, which is 15% lighter than steel, non-magnetic, and easily lubricated, are expected to be integrated into the ISS’s water recycling system by the end of the decade. It could also become an essential component for several commercial applications, specifically in aerospace and marine applications.

“Once we’ve demonstrated the technology for a space project, then we can use that same bearing for other space mechanisms, and the companies that make the bearings can sell them to manufacturers,” he says.

With NASA technology, getting from innovation to commercialization can be an arduous process. One of DellaCorte’s first projects in the mid-’80s was working with solid lubricant coatings and air bearings that are now emerging in fuel cell blowers, microturbine generators, and turbochargers.

Technically, the genesis of nickel-titanium bearing, which DellaCorte calls a “stumble upon technology,” began in the Eisenhower era, when Sputnik had space all to itself.

NiTiNOL 60 (60NiTi) is closely related to the NiTi shape memory alloys developed at the Naval Ordnance Laboratory in the 1950s for missile cone applications, hence the suffix “NOL.” The peculiar superelastic properties of shape memory alloy—which if deformed, will spring back to its original shape when heated—had always intrigued DellaCorte.

This was fortunate for Abbott Ball Company, based in West Hartford, Conn. Engineer Glenn Glennon realized the potential of 60NiTi as a tough, non-corrosive bearing material, and wanted NASA to test it out. DellaCorte would usually reject such a request so as to not appear partial to or endorse a commercial enterprise.

“The thought of working with this new family of alloys was intriguing, yet my skepticism concerning the use of titanium as a bearing material remained,” the tribologist says.

“I didn’t believe it because most titanium alloys gall, they stick, DellaCorte explains. “If you try to screw them in, the bolts will jam, and you can’t add grease or oil. You have to cover up the titanium with some other material.”

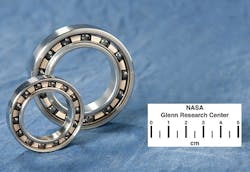

After agreeing to work with Abbott, NASA soon realized the conventional process yielded misshapen ball bearings, so DellaCorte implemented a powder metallurgy process at NASA Glenn’s facility, which created smooth, pure bearings. Abbott then refined the process for mass production. NASA and the bearing company share several patents.

Not only did they create a bearing that wouldn’t rust, but it won’t even scratch.

“We discovered you could take that family of materials, that was dimensionally unstable, add a little extra nickel to it, and it loses all that really cool dimensional instability, but it gets hard,” DellaCorte explains.

Hard is an understatement.

“You can hit it with a hammer and it doesn’t dent,” says DellaCorte. “You could put 10,000 lb. on it and not dent it.”

With other bearings, the extreme vibrations of the launch can shake the balls and put dents in the races, causing the bearing to "run rough," DellaCorte says.

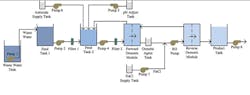

That is ideal for the distillation assembly on the wastewater recycler, which if you don’t know, is the machine that allows astronauts to drink their pee.

The process works similar to an earthbound rotary distiller: the shaft rotates the drum (at 200 rpm) and centrifugal motion forces the liquid to the sides. The heated drum turns the water molecules to steam, which is collected in a separate chamber, while the waste is separated and evacuated.

In this process, the liquid is urine and sulfuric acid is used to treat it.

As you can imagine, the outside of the bearings get “splashed with all the bad stuff,” DellaCorte says. The current cobalt alloy bearings don’t corrode but are relatively soft and subject to wear even under light loads.

Currently, NiTi ball bearings have been made in sizes ranging from 12.7 to 50 millimeters bore (inside diameter). Sliding-type spherical bearings (ball and socket) have also been made and have shown to be fully compatible with aircraft deicing fluid and hydraulic fluid.

“In aircraft applications, the bearings along the wings and control box gearboxes get wet with de-icing fluid and water. This material can be used for those bearings and it’s not going to rust,” says DellaCorte.

These bearings are ready for commercialization, and NASA has signed a Space Act Agreement with Kamatics Corp. to develop swivel bearings for aerospace applications.

DellaCorte says future work will be centered around developing cost-effective methods to make small bearing balls, as small as 1 millimeter in diameter, and smaller bearings (6.35 millimeters bore) to support the growing small satellite industry.

The spacesuit pump would have a 1.25-inch bore and is only theoretical at this point. For a company to commission a specific size would possibly cost $250,000 and take several months to years because of tooling and testing demands.

The bearings may cost five to ten times more than steel, DellaCorte says, but for highly expensive operations, such as on an oil rig, using a material with so many amazing properties would be well worth it.

“If the price of failure is high, you really don’t care what the bearing costs,” DellaCorte says.

NASA’s motto is “For the Benefit of All,” and spurring new innovation on Earth is certainly a benefit. The 60NiTi bearings represent a perfect union of government and business, as NASA may not have thought to use the material on its own, while Abbott did not have the resources to complete the R&D.

Now any company can contact NASA Glenn’s technology transfer office to find ways to leverage existing technology. And if your company has stumbled across its own innovation, someday it could wind up helping astronauts stay hydrated, or keep them from drowning.

You never know.

“Technologists need to keep their eyes open because you never know where some new solution is going to come from,” DellaCorte says.