In the industrial world, the allure of wearables can be intoxicating.

For nearly a decade now, workers have been promised a wild array of gadgets and accessories designed to improve their lives, to make their work easier, better, and faster; to give them the high-tech boost we all so desperately need.

New developments in the market have fed an expectation of a kind of bionic workforce—a hyper-efficient army of connected workers plugged directly into the data stream, covered by complex gadgets feeding them information in blips and bleeps, videos, and on-demand schematics, connecting them with experts, maps, plans, and instructions overlaid on the world in front of them whenever they need them, wherever they need them, without even pushing a button.

If that's the expectation, everything we've seen so far has been a letdown.

What was promised as a revolution, turned out to be clunky monocles too goofy for the consumer world and too weak for the industrial.

We got, at best, fairly cool technologies with no practical applications to give them traction.

We were promised productivity, and we got gadgets with half the functionality a smartphone stuck to our faces and wrists. We got glassed-out distractions and expensive toys.

However, there is still hope. Looking over the range of latest-generation devices coming onto the market this year, this letdown may soon end. If these products live up to their potential, 2016 may be the inflection point the wearable market has been waiting for.

The M3000

One device particularly poised to deliver some disruption to the industry is Vuzix's M3000 smartglasses.

Revealed to the world just this month at the 2016 Consumer Electronics Show (CES) in Las Vegas, the M3000 represents a two-year mission to create a pair of smart glasses that are slim enough, sleek enough, and powerful enough to fulfill all of the productivity-boosting promises the technologists have been teasing.

The results were rather incredible.

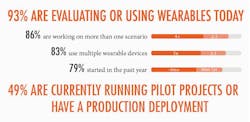

The study, published as "The State of Enterprise Wearable Technology," found that nearly every industrial company already has active evaluation, projects, or deployments of some kind of wearable device in the works.

In total, 93% of these companies are either evaluating or using the devices already and 97% of them indicated they are interested in them for the future.

That kind of penetration is ridiculous even by hype standards.

"These companies have recognized this technology as an opportunity to connect an entire cross-section of the workforce that has been underserved by information technology," Ballard explains. "They see these as a driver of productivity and safety inside plants and in the field. They recognize that these technologies have real and measurable value."

However, this 93% of companies exploring the technologies doesn't mean that 93% of the workforce is already using them.

The figure represents the real potential of the market—a swelling demand bubble ready to explode as soon as the timing, the hardware, and the software all align just right to help make these potential customers invest.

"You've got IT, you've got the line business unit, you've got workforce training as part of it. All of those pieces, plus the technology of the wearable devices themselves and the infrastructure around that technology all have to converge at the same time for this to really take off," Ballard says.

It looks like we are quickly approaching that point.

"Look at the market now," Ballard notes.

"You've got high data rate, higher liability low-cost wireless communications, almost ubiquitously installed for most companies. You've got wearable technologies that are available at scale.

"Everything is right for wide-scale enterprise deployment. The market is ready and so is the technology."

What Will Wearables Do?

Okay, so the time is right. The technology is there and manufacturers are ready to use them. But what can they do, exactly? What does seamless connection to data actually do for a worker on the floor?

Mostly, wearable makers like Vuzix focus on three elements for the industrial market:

1. Service

The first, and probably the easiest element, explains Lance Anderson, VP Enterprise Sales at Vuzix, is service support.

With the video streaming and heads-up display of smart glasses like the M3000, he explains, workers encountering an issue with a machine can have immediate access to service technicians and experts around the world who can walk them through solutions, maintenance procedures, or more accurately diagnose issues for further support.

"This drastically improves the service levels to clients. It's almost like the expert is sitting right there next to them," Anderson explains.

"It means that a piece of equipment—their trucks or their machines or tractors—is up and running much faster and they're not losing money. And of course, it means that the actual service provider doesn't have to fly out there to fix it.

"You're multiplying that expertise across multiple clients."

2. Traceability

With the video recording functionality of these systems, every step in the work process can be recorded and cataloged. Rather than relying on notes and vague data logs, the system can compile and share the entire process from start to finish. It takes traceability to a whole new level.

"Think about pharma compliance," Anderson says.

"You have to follow all of the FDA rules, track and trace and all of that. Now you have it visually—you can see where everywhere it went, every step of the process. It keeps perfect records."

Better yet, it provides this without requiring any extra work or processes by the workers or managers on the floor. Every step is recorded in the process as part of the normal work function, saving time while also significantly increasing the quality of the data.

3. Quality

This, of course, is the big one.

The pitch is essentially this: when workers encounter an issue or problem, they don't have to break from their work to consult manuals or a computer reference somewhere.

They don't have to call in superior or experts. They just bark a few voice commands and the entire process—complete with checklists, schematics, pictures, and drill-down information—is brought right up and displayed side-by-side with the real thing.

"The really unique value here is in enabling the workforce to use it as a tool for when anomalies happen," Anderson says.

"It enables them to take steps to go and resolve an issue, whatever it may be. It enables the workforce to do things right the first time, every time."

This, Travers argues, is the real selling point for the technology.

"When users put these on and their picking rates start going up and their error rates all drop to zero and their jobs get easier, it doesn't take long before they want to keep them on all day long," he says.

And that doesn't seem to be much of an exaggeration.

"We’re not talking single-digit bumps in quality. We're talking double-digit percentages," he says.

"A lot of the customers we are working with are seeing drastic improvements that justify investing in smartglasses with Skyline and seeing an ROI in one year.

Workforce of the Future

The closing argument for all of this—as it is with everything lately—comes down to the workforce.

We all know the story of the shortage of millennial workers and of the looming threat of mass baby boomer exodus from the workforce. We're facing a very near future of skilled worker shortages and a persistent challenge to bring young workers into the manufacturing space or engage those that do enter.

These devices seem to offer an immediate solution to some of these issues.

First, there is the sexiness angle. Offering young workers the opportunity to wear smartglasses and awesome connected devices still largely unavailable or impractical in the real world makes the manufacturing world all the more appealing. It adds to the growing notion that manufacturing has evolved from its dark, dirty, and dangerous past to an amazing, Star Trek future.

But more critically, it is helping to hold onto the critical experience and know-how the industry is losing in retiring boomers and training their replacements with the skills they need to continue the effort.

This part, Anderson notes, is already happening.

"Here's a true story," he says. "We have these gentlemen in their 50s and 60s. These are guys who have been in facility service, working in HVAC and roofs for years, but they can't do it anymore. They can't physically perform the task anymore. They start to feel useless."

With these new devices, he says, these guys can finally get back to work. They can't physically climb the ladders anymore, but they can climb them virtually with the younger workers, seeing what they see, hearing what they hear, and working right beside them through the job. They have become indispensable experts training a whole new generation of workers, Anderson says.

"Now with this technology, this is a whole new life for them. Their career can still go on," he says. "They can retire down to South Carolina but still be very effective remotely helping these guys train. They feel good, they're happy about it .

A Tool is a Tool

After all of this, it's probably safe to stop referring to these devices—as we probably too often do—as some kind of sci-fi-inspired, superfluous gizmo.

If this new generation of tools work as they're reported to work and do what they're said to do, we can probably call this the end of the hyperbolic promises and expectations.

If these wearable devices are to succeed on the plant floor or in the field, or wherever they are deployed, none of this will matter.

All the workers need are tools. Equipment to make their work easier, better, and faster.

And this, it seems, might be what they are finally getting.

"I'd rather not think of these as these smart devices, smart glasses," explains Jay Kim, Chief Strategy Officer at APX Labs.

"Really at the end of the day, they are a tool to make people work more efficiently, not unlike some of dumber tools in the past like torque wrenches, multimeter and so on and so forth.

"These are just the next generation of tools that are available to the next generation of workers."