In tool and mold construction, highly abrasive graphite materials and extremely hard materials such as alloy steels of up to 65 HRC or more are dominating the scene. Enabling the cost-effective creation of 3D contours and shaped elements, for example, imposes particularly demanding requirements on the mills and on process management. Tool manufacturer Inovatools, from Haunstetten near Kinding in Germany, is providing the North American metal industry with a broad product range of high-performance solid carbide mills that meet the exacting requirements in mold, fixture, and die manufacturing.

Moldmakers need tools that they can use to produce molds, dies, matrices, and electrodes of high quality as quickly as possible and above all, economically, while observing the narrowest of production tolerances. Douglas Kline, Managing Director of Inovatools USA LLC, says, “Our special range of mill products is designed for the most varied of applications in this machining segment. The tools have been adapted for the relevant applications and materials in terms of substrate, geometry, chip control, and coating.” They include universal, roughing, finishing, and special mill series such as mini-shank, copying, and full-radius end mills in a wide array of designs and dimensions and featuring application-optimized high-performance coatings.”

“First Choice” Helps You Quickly Find the Right Tool

In addition to in-person technical advice, Inovatools gives users the opportunity to find tailor-made tools for their specific cutting requirements quickly and easily with “First Choice Inovatools.” As Kline explains, “First Choice Inovatools is a powerful instrument and our special recommendation for quickly identifying top tools in the Inovatools online shop or in the main catalog, including for tool and mold construction. With the INOCUT cutting data program, users can search for tools by the application and specified cutting values. In the complete catalog, the tools are marked as ‘First Choice’ accordingly. One of the things we are trying to achieve is to guide tool manufacturers and moldmakers to the advanced geometries and technologies that are most suitable for them via the fastest possible route. Ultimately, that helps them to reduce production times and deliver top surface quality while benefiting from a longer service life, for example.”

“Prevailing over” Steel Materials with FightMax

For steel processing, Inovatools is sending the FightMax and FightMax INOX mill series (for stainless steels) into the ring. With their exceptionally smooth surfaces and a special high-performance coating that provides a high resistance to heat, FightMax mills can withstand high levels of tool wear over very long periods, even at high feed rates and cutting speeds.

Better Milling with CSC Curve Segment Technology and CURVEMAX

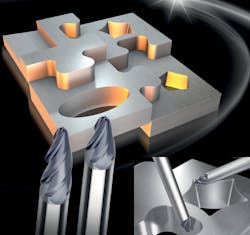

The solid carbide curve segment cutting (CSC) mills in the CURVEMAX series are an example of Inovatools tool technology with adapted process technology for copy milling. In tool and mold construction, the solid carbide curve segment mills in tangential and conical form shorten the process times required for finishing complex, freeform surfaces in a wide variety of materials.

Thanks to their special geometries, Inovatools CURVEMAX mills permit bigger path distances and line jumps during pre-finishing and finishing. Although the working radius is larger than that of a traditional full-radius mill, the tool still has the same diameter. This leads to a significant reduction in process times. Thanks to the larger engagement width, the cutting edge does not suffer from wear at any point. Combined with the extremely smooth, high-performance VAROCON coating, this helps to increase the tool’s service life. The larger and flatter overlap reduces roughness and ensures surface finishes even better than those created by traditional full-radius mills. Inovatools offers the new CSC-CURVEMAX mills in conical and tangential form as four-edged cutters for finishing in different sizes and radii.

The curve segment milling technology also opens up new production options. For example, undercuts, freeform surfaces, and variable setting angles can be reliably created. In addition, complex contours can be pre-finished and finished, even on narrow inside radii.

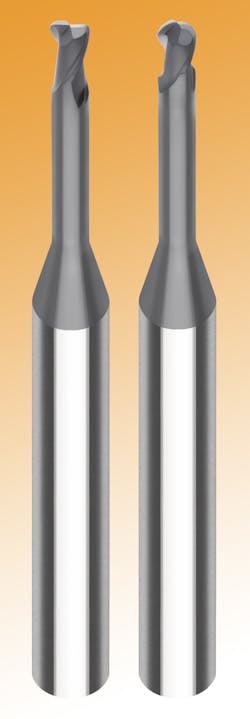

Manufacturing Graphite Electrodes Cost-Effectively with Dia-Dur

According to Kline, “HSC machining of graphite electrodes, for example, using diamond-coated tools is the method of choice in tool and mold construction. Only using high-quality, robust tools can cutters comply with narrow tolerance zones while milling materials quickly and cost-effectively."

Inovatools has copying and ball nose end mills featuring the special Dia-Dur coating in its range for machining graphite electrodes. The excellent adhesion properties of CVD high-performance Dia-Dur coating gives the Diamond edition tools similarly good physical and chemical properties to that of natural diamond. They offer exceptional performance and are tremendously robust thanks to their extreme hardness and smoothness, high chemical resistance, excellent thermal conductivity, and abrasion resistance. For example, a layer thickness of 10+2 µm gives the copying end mills of the DIA DUR ER series a long service life.

With the Diamond edition, Inovatools highlights its comprehensive expertise in this area. For example, the end mills (tolerance H5) with radius tolerances of +/- 0.003 mm are ground with extreme precision, and the concentricity of the full and corner radius end mills is 0.005 mm. Selected carbide grades are essential to ensure consistently high quality.