Thermoplastic Functional Coatings and Composites

Generally, composites, such as glass fiber and carbon fiber, are popular materials among manufacturers because of their light weight and mechanical properties compared to traditional materials, such as steel and aluminum. Composites can also be designed to take advantage of special coatings that help aid their integration into a product while improving functionality.

There are two main categories of resins used when producing composites, thermosetting, and thermoplastic. Thermosetting resins, which are the more common of the two types, harden through curing, forming heavily cross-linked polymers with insoluble or infusible rigid bonds that will not melt when exposed to heat. While not as common in pultrusion, thermoplastic resins are increasingly being explored.

Thermoplastics are branches or chains of monomers that soften when heated and solidify when cooled. This is a reversible process with no chemical bonding, meaning you can re-melt and re-form them as needed and mold them to fit virtually any shape.

Thermoplastics that can be used with composites include, but are not limited to, thermoplastic polyurethane (TPU), poly(methyl methacrylate) (PMMA), polyethylene (PE), polyamide (PA), and Polypropylene (PP).

Advantages of Thermoplastic Functional Coatings

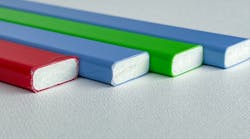

There are advantages to combining a thermoplastic functional coating with a thermoset composite. By extruding thermoplastic functional coatings as a step in the composite’s production, manufacturers can provide additional mechanical properties, such as shock absorption, the bond strength between components, grip, and corrosion resistance, as well as add more aesthetic possibilities in profile designs.

The thermoplastic coating allows manufacturers to offer wider finish possibilities, so customers can have an expanded range of products with shiny, matte, rubber or even metallic appearances, allowing seamless integration with existing structures. The metallic-looking finish is popular because composites are often used as replacements for metal parts in existing structures and this allows them to blend in visually.

Thermoplastic coatings also offer practical benefits for end users. For example, when thermoplastic coatings are used for telescoping components, the improved friction between the tubes and locks means that the telescope can withstand more force before collapsing.

Carbon fiber has extremely good mechanical properties, offering the desired strength and weight, but sometimes it does not have the necessary friction and/or adhesion properties for the application. By coating the carbon fiber composite with a thermoplastic coating, the product can gain the required friction and adhesion properties, as well as additional protection for the composite from environmental factors, such as weather, water or other damaging circumstances. This could be useful in examples such as marine applications, strata control or tension members.

Exel Composites has developed expertise in continuous composite manufacturing processes, such as pultrusion and pull-winding, and provides in-line functional coatings of composites during the manufacturing process, instead of the more typical approach of adding coating post-production. This allows customers to take advantage of all the benefits of thermoplastic-coated composites, such as shock absorption and corrosion resistance while reducing manufacturing complexities.

Furthermore, because of the precise fiber alignments and process controls, pultrusion and pull-winding ensure consistent production quality batch-to-batch and are highly repeatable.