Best Asset Condition Monitoring Practices for Forging

The metal forming industry demands high-precision manufacturing methods. Condition monitoring of hydraulic or large, mechanically driven machines—for example, forging presses—is of critical importance for the proper functioning of these plants. Thermography, pressure, vibration, and oil analysis are used to collect important data for predictive algorithms and form proactive maintenance processes. Next-gen CMMS (computerized maintenance management systems) are used to analyze this data in the context of other important readings and provide maintenance professionals with a 360-degree insight into how the processes are running.

Collecting and analyzing real-time diagnostics from all plant production assets supports predictive analytics to prevent potential failures and identify underperforming assets, thus reducing downtime, minimizing maintenance costs, and extending equipment life.

Making Smart Manufacturing Smarter

As the Industry 4.0 phenomenon continues to expand its functionality and influence, forging plants are being transformed into connected systems, increasingly relying on valuable predictive maintenance techniques. Very soon digitalization and the integration of industrial systems will become indispensable for competitiveness and quality production.

Condition-based data is important but quite limited without being stored in a CMMS and connected to all the other available asset data, such as previous readings, intervention history, and spare parts.

Combining predictive maintenance and CMMS in one seamless system increases machines’ availability and reliability. The result is the creation of powerful predictive algorithms that immediately boost the effectiveness of the overall maintenance process.

Lionel Mochamps is the maintenance manager of a warm and cold forging operation producing a wide variety of industrial components, part of the French manufacturing group Farinia. “In the last two years, we have totally changed our maintenance process,” he reported. “It was challenging. but every single effort was absolutely worth it.

“We implemented a new next-gen CMMS that stores and analyzes our entire asset condition monitoring data,” Mochamps detailed. “The plant’s unplanned downtime has been cut by 80% and the production cycle has drastically improved.”

Beyond these successes, he noted with satisfaction that the Mobility Work program did not require any specific set-up or additional training. “It's actually a whole maintenance manager platform with a social media aspect,” he noted. “Every team member was happy to implement it in the daily routine.”

Predicting Equipment Lifecycle

Forging plants maintain large numbers of assets in their production portfolios, and understanding the condition of those assets during the various stages of their performance lifecycle is critical to cost management. Condition-based monitoring data is periodically obtained and analyzed in the context of predictive strategies through a CMMS to determine if an asset needs a repair and how much useful time the asset has left.

Fixed assets management is crucial for a good condition monitoring cycle. Fixed assets lose value as they age and are subject to periodic depreciation after each retrofit or rebuild. The nearby diagram illustrates the asset management cycle of the above-mentioned forging plant.

Once a new piece of equipment has been purchased and passed the first level of depreciation, its net value should be recalculated before entering into the obsolescence phase and attaining the second level of depreciation. Some parts are at higher risk of becoming obsolete and require proactive management, including predictive strategies and corrective actions.

Then, the machine or critical spare parts are evaluated and—depending on their status—are completely replaced or retrofitted. If retrofitted, their NPV is calculated again and they enter into the third stage of depreciation.

Predicting Equipment Failure

To predict when an equipment failure might occur and to prevent this failure, predictive maintenance employs a wide range of techniques, varying from one industry to another. Below are some of the best condition-monitoring techniques, applied in the forging industry.

Depending on the quality and the role of the equipment, they are performed with different frequency. For example, a broken bearing might be predicted six months in advance, while the frequency of replacing a part on a high-speed machine will be much lower.

Vibration Analysis

Vibration analysis monitors the changes in vibration due to shaft misalignment, imbalance, defects in rolling-element bearings (enveloping), and/or mechanical looseness.

The sensor for vibration analysis measurement is placed on the bearing to record a spectrum of vibrations and provide two significant values. The first value should be below 7 and the second one below 50. If this is not the case, a default has been detected and its exact origin should be investigated by analyzing the spectrum. For instance, if the frequency has doubled, then the possible reason could be a misalignment or an imbalance.

Oil Analysis

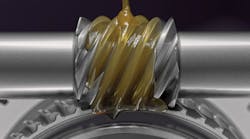

Lubricants protect forging equipment from corrosion and dissipate heat from surfaces. Problems with a lubrication system can be figured out through oil analysis. To optimize maintenance costs, a sample of oil can be tested once a year when oil filters get replaced or depending on the equipment other routine operations are performed.

Thermography

Because heat is an early symptom of equipment damage or malfunction, thermographic testing is performed once per year for all electrical cabinets and transformers at the forging plant to indicate “hot spots” and to plan refurbishment. To be sure that all relevant equipment is properly checked, an inventory list from the CMMS is used.

Non-Destructive Testing

Some reliable non-destructive testing methods in the industrial sector include penetrant testing and ultra-sound check on workpieces susceptible to cracking. Aerosol penetrating products are applied, and 10 minutes later the crack that is invisible to the naked eye is revealed.

Wear Measurement

A lot of predictive controls can be done by a simple measure of wear parts. If the measurements indicate a low thickness, a replacement is immediately scheduled.

Amperage Measurement

Amperage measurement with a certain ammeter check can highlight an engine overheating or a mechanical malfunction.

Since all the condition monitoring techniques mentioned here are very expensive and at the same time limit the availability of a machine while being performed, their precise and reliable performance is of critical importance.

Predictive maintenance uses the above-mentioned condition monitoring techniques to create algorithms and predict the wear or end-of-life of a certain component, in order to plan its “just in time” replacement, or to schedule replacement when the equipment is not engaged. However, to create actionable decisions and improve the overall maintenance management, PdM data, and CMMS should be combined in one system for a most successful predictive maintenance strategy.

Hot and cold forging processes require expensive, heavy-duty manufacturing equipment. Maintenance is critical to ensuring reliable and competitive production cycles. The right condition-based monitoring techniques will ensure reduced downtime, workers’ safety, cost optimization, and longer equipment life.

Ralitsa Peycheva is a technical content manager at Mobility Work, a developer of computerized maintenance management systems for industrial operations. Follow her on Twitter.