Latest from Quality Control

New Article

AI-Powered, HD 3D Scanning

Quality Management Software Release

How to Track Maintenance Costs

X-Ray Inspection Made Easy

Pyrometer Series Extended

High-Speed IR Camera

Multifunctional Thermal Flowmeter

Back on Track with Oil Analysis

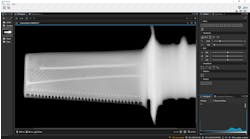

Even near-net-shape forgings need precision machining to achieve their full value potential — and the requirements of machining become even more precise, more demanding, all the time. But, expert machinists can learn from forgers, too. Consider the “hammer forged” barrels that are featured on many firearms. They are not well regarded by precision rifle shooters, but suddenly a manufacturing process developed by forgers and widely used in hammer forging is getting attention from custom barrel makers today. It’s honing.

Honing produces a high-quality bore surface fast, which is critical to hammer forging. Surface imperfections in a barrel blank before hammer forging will tend to be amplified as the blank is formed on the rifling mandrel. And, if the bore is chromed afterward, imperfections in the surface finish become even more obvious.

Surface finish is the one feature of the barrel that cannot be controlled in hammer forging (“garbage in, garbage out,” as the saying goes.)

You may wonder, “What about a reamed bore finish?” Sure, hammer-forged barrel blanks are gun drilled and reamed, just like all barrels, but a reamer starts to dull once the first part is processed. After that, scratches in the bore get rougher. For this reason, makers of hammer-forged barrels regularly hone the bores of barrel blanks to enhance the product and improve process consistency.

Honing improves bore-diameter size uniformity and accuracy, surface finish and roundness throughout the length of the barrel. It can certainly be used in place of a pre-rifling lap. The chief difference between a lapped and honed bore is the direction of the finish lines in the bore.

Honing leaves fine spiraling crosshatch lines, while a lap leaves lines that run longitudinally in the bore. After rifling, the manufacturer can remove the crosshatch finish with a quick lap if desired.

Honing is fast, accurate, and it can be automated. Its surface quality and geometry can duplicate lapping, except for the longitudinal lines of the lapped finish. Honing is one of the processes used to make affordable, mass-produced, hammer-forged barrels that regularly hit “minute of angle” (MOA) accuracies.

MOA accuracy may be insignificant to precision benchrest shooters, but it’s a breakthrough for the consumer market, and the competition to achieve such accuracy has some manufacturers bragging about half-MOA as their new standard.

For custom barrel makers, honing is a timesaving and cost-cutting approach to accuracy. A few minutes on a honing machine can cut lapping times in half, leaving a crosshatched surface finish in single or low double-digit Ra. Honing is the same process used to make diesel fuel injectors with bore roundness and straightness controlled to fractions of a micron (<0.000040 in.), with surface finish Ra ≤0.15 µm (6 µin).

The maker of these machines, Sunnen Products Co., has been supplying defense contractors and commercial firearms manufacturers for decades. Recently, the company recently introduced a new machine for .17- to .50-caliber honing. Its spindle can correct bore-size imperfections so small only an air gage can measure them. Early users aim to make sub-minute accuracy the norm for their standard rifle barrels.

Custom barrel makers are catching on to this, too, so it’s time for a tip of the hat to the hammer forging guys that led the way.

Dave Sengelaub is an applications engineer with Sunnen Products Co., a manufacturer of honing systems, tooling, abrasives, coolants and gauging for precision bore sizing and finishing. Visit www.sunnen.com