Forged nuclear reactor components produced by Areva’s Creusot Forge operation continue to be under investigation, following a report that French nuclear regulators found weak points in steel parts supplied for the European Pressurized Reactor (EPR) III being built at Flamanville, France. Pierre-Franck Chevet, who leads the regulatory agency ASN, told Le Parisien newspaper that weak spots in the bottom and lid components of nuclear reactor pressure vessels designed by Areva could reduce the resistance of the metal, raising the risk of a reactor failure.

"This is a serious, even very serious anomaly as it affects an absolutely crucial reactor component on which no risk of rupture can be taken," Chevet told the paper.

Areva, has said it is conducting analysis of the production process for forged parts of the Flamanville 3 reactor pressure vessel (a project it is developing for state utility Électricité de France, or EDF), and is reviewing similar analyses previously conducted on other forgings, according to the terms of French regulations on nuclear pressure equipment.

The regulator also noted that production sequences similar to what was used for the Flamanville 3 reactor were involved for five other EPR vessels, planned or being built.

Areva is a multinational organization active in nuclear energy system design, development, and operation. Its EPR pressurized-water nuclear reactors are installed at several power plants in Europe and currently scheduled for two new installations in China.

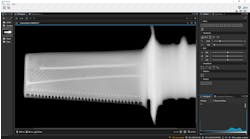

In addition to designing and building reactors, Areva operates Areva Creusot Forge, a specialty manufacturing and machining operations for nuclear forgings and castings. The forging operation there is among a handful anywhere in the world producing parts needed to build nuclear reactor vessels.

Together with the forging process review, Areva is reviewing a mechanical testing laboratory at Creusot Forge, where hot-tensile testing procedures used from 2009 through 2014 were found to have been inaccurate.

Areva emphasized that the laboratory review does not indicate a problem for the manufactured components, but rather a malfunction of its quality inspection methods that requires reinterpreting results or repeating certain tests. “The assessments performed since have demonstrated that the results are in compliance with requirements, due in particular to the redundancy of the testing and inspections,” Areva stated.

“These assessments have confirmed thus far the intrinsic quality of the forgings and the safety of components,” it continued. “This verification continues and will take several months. None of the components concerned by the inaccuracy of this inspection tool are installed in nuclear power plants in operation.”

Areva, with consent of ASN and EDF, said it would enhance its internal evaluation process with an external review of areas related to forging and inspections. It will enlist an independent expert, Lloyd’s Register Apave Ltd., to conduct this review.

The external review will begin on May 4, 2015 and continue for at least two months. Areva said it will help it to identify the causes of potential defects in practices and in quality inspections, as well as the measures to take to continue with improvements at Creusot Forge.