Latest from Quality Control

New Article

AI-Powered, HD 3D Scanning

Quality Management Software Release

How to Track Maintenance Costs

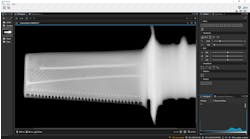

X-Ray Inspection Made Easy

Pyrometer Series Extended

High-Speed IR Camera

Multifunctional Thermal Flowmeter

Back on Track with Oil Analysis

Surface Measurement/Analysis with High-Speed Column Drive

TAYLOR HOBSON’s new Talyrond 500H precision surface measurement tool features a high-speed column drive, precision positioning and 4-mm roundness and contour gauge. The instrument incorporates Taylor Hobson’s experience in high-accuracy surface measurement with its expertise in ultra-precision machining.

The Talyrond 500H relies on a low-noise metrology frame, an accurate axis alignment and a patented data collection method. Together they provide the Talyrond 500H with unmatched straightness and roundness measurement capabilities that allow it to exactly reproduce the shape and contour of a precision machined component.

The instrument’s high-resolution gauge measures linear or circumferential surface roughness; its frictionless air-bearing spindle and precision column measure roundness, cylindricity and straightness, while a patented calibration technique performs radius, angle, height, length and distance measurements.

Talyrond 500H is well suited to a wide range of high-accuracy measuring applications, including precision bearings, fuel injectors, crankshafts and turbocharger parts. In addition, Taylor Hobson offers a comprehensive range of standard accessories along with a long list of highly specialized accessories that allow the instrument to accommodate the industry’s most demanding applications.

The Talyrond 500H provides high-productivity and error-free performance regardless of operator skill. It performs calibration, center and level functions, along with measuring routines, automatically. These features along with simplified teach and learn programming techniques, comprehensive user prompts and on-screen instructions combine for unparalleled ease of operation.

Inaccuracies in roundness, form, and surface finish often are the result of turning, honing and grinding by the machine tools used to create the component. With its ability to accurately duplicate a machine tool’s movements and exactly reproduce a work piece shape, the Talyrond 500H provides its users with rapid feedback to rectify production issues that may cause inaccuracies.

Assembly of round mating parts, for example, can be problematic when one or both of the parts are oval or lobed. These low-frequency harmonic problems are commonly caused by excessive part-clamping pressure or result from unstable machining forces. The Talyrond 500H identifies these problems with a simple roundness measurement and harmonic analysis and quickly provides the necessary information for their correction.

Visit www.taylor-hobson.com