Plant safety is not a competition, but the best performing operations deserve some credit, or even reward, for their achievement — and to set a standard for other manufacturers. Generally, high safety standards are their own reward, though there are certainly other benefits to plants that implement effective safety standards and maintain sound records for safe operation. Among these are insurance cost savings, worker loyalty, and in the forging industry the FIA’s Annual Safety Awards program.

Each year the Forging Industry Assn. surveys member companies to document safety performances, tracking OSHA reportable Incidence Rates and Frequency Rates at different plant sites to identify the leading plant-safety performers in the industry. The annual Safety Awards are presented to forging companies in four groups, according to the average annual employment at each location.

Information for the competition is gathered via questionnaires delivered annually to all FIA producer members. Each plant provides data recorded on OSHA Form No. 300, “Summary of Occupational Injuries/ Illnesses for Calendar Year” for U.S. companies, and from Worker’s Compensation Reports for Canadian companies on the questionnaires.

Two rates are computed for each participant: DART -- Days Away from work, work Restrictions, or job Transfer cases -- Incidence Rate, and Frequency Rate. The published report provides a summary for the total industry and detailed company rankings, according to the Incidence Rate by size groups.

FIA presents first-, second-, and third-place Safety Award plaques to plants that have the lowest Recordable Cases Incidence Rate, provided that the DART Incidence Rate falls below the group average. In the event that Recordable Incidence Rates are equal, FIA assigns the award to the plant with the lower DART Incidence Rate.

Awards for improvement are presented to plants that demonstrated the greatest decrease in the DART Incidence Rate. This is determined by percentage of improvement by DART Incidence Rate compared with the average of the preceding three years.

A certificate of recognition is awarded to each company that does not earn a first-, second-, or third-place rank, and where the Recordable Incidence Rate falls below the group average — provided that the DART Incidence Rate also falls below the group average.

One of the inherent difficulties of developing a successful safety program is that there are no perfect examples to follow, because every plant is different, as is every workforce. The variables are the details that must be managed.

Each award is the result of a daily effort by plant managers and safety engineers to develop and maintain high standards in their operation. We sought more insight on those efforts from the forging operations that took top honors in FIA’s 2013 survey.

A Challenge Every Day

Lakeview Forge Company in Erie, PA — the top honoree among forging plants with 80 or fewer employees — is a closed-die operation, producing custom forgings that range in weight from just a few ounces up to 15 lb. In addition to forging, theLakeview Forge’s safety is based on monthly safety “tours” to document conditions and emphasize workers’ awareness, along with monthly meetings to review current status. “Any safety issues are confronted and taken care of that day, as the problem occurred,” Mennini indicated. “Safety and good housekeeping are part of an ‘everyday working procedure.’ Accidents are reviewed and investigated to prevent any injuries.”

Worker safety training is conducted as needed, but Mennini added that Lakeview’s safety program prioritizes efforts to keep employees aware of safety issues that may occur on the job, as well as the specific safety issues that attend to individual machines and equipment.

Making certain that workers are mindful of their own role in maintaining safety is another core principle for Lakeview Forge. This includes ensuring that all workers always wear proper safety equipment, keeping them involved in safety committee discussions and plant safety tours are part of this initiative, too.

The results during the past year have demonstrated Lakeview Forge’s effectiveness at establishing a safety habits in the workplace, and the effort now turns to maintaining those habits. Mennini noted this would start with the operation continuing to review “programs, policies, and procedures” and remaining active in the effort to observe, emphasize, and train the workforce to maintain sound practices. “Don’t wait for an employee to get injured, or to complete a safety tour before taking care any safety issues,” he advised, as much to other forging operations as to his own.

Seamless Rings, Comprehensive Approach

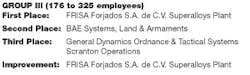

Frisa Forjados Superalloys Plant in Monterrey Mexico, the award-winner among plants with 176-325 employees, supplies seamless rolled rings to aerospace and power-generation industries. The 127,713-sq.ft. plant hasAs explained by Augusto Ponce, Frisa’s environmental health and safety leader, the safety challenges there mainly involve material handling, “because of the dimensions of our products (rings up to 196 in./4,980 mm diam.); cuts and lacerations due to our machining operations; and fire hazards in our presses and rolling operations.”

The program is comprehensive. Frisa’s Safety Committee reviews leading and trailing indicators on a monthly basis, including all accident and incidents investigations. “We investigate every incident, accident and property damage in our facility,” Ponce explained. “Housekeeping and 5S program are a joint effort with Safety, and weekly walkthroughs (led by the plant manager and including all first-line supervisors) have been implemented to identify any unsafe condition or operation.”

In addition, Frisa tracks leading indicators, including safety training program compliance, Job Hazard Analysis completions for new/modified operations, behavioral observations and trends, 5S program results, and safety survey scores and comments.

These are in addition to the trailing indicators, which include the DART (per 100 employees), Severity (days away or restricted duty days/100 employees) and Total Incidence Rate (TIR), which includes total accidents plus property damage incidents/100 employees).

“We have basic safety training for all new employees,” Ponce said, “and after that, depending on their work area, specific training will be given which includes technical, safety, and quality skill development.”

The maintenance department holds “pre-task meetings” as required by specific projects, involving a risk assessment of the area and all personnel involved (production, maintenance, sub-contractors and safety) in the task. Ponce noted that “safety metrics are part of the KPIs of each plant and of management in general.

“On a supervisor/plant manager level,” he continued, “Safety Committee meetings are held every month, at which all safety related incidents are discussed, as well as legal compliance, and leading/trailing indicators.”

In addition to basic and specific safety training, the Superalloys Plant emphasizes safety with constant displays of safety messages in common areas (production boards, cafeteria, newsletters, etc.

Worker engagement is also achieved with a voluntary program of “Safety Leaders,” designated operators from each department who are given safety-oriented training (ergonomics, risk assessments, accident investigation, communication skills, etc.). These leaders are in charge of weekly safety talks, keeping an eye on new employees and sub-contractors, and helping with incident/accident investigations, among other things.

“They are identified differently, for example a red hard-hat or a red t-shirt,” Ponce detailed, “and they select the safety talk material depending on the conditions and observations in their area, and what they feel needs to be addressed.”

He said this companywide program has been proven to be hugely successful, helping to promote the safety culture and expand the work force’s engagement on plant safety issues.

This is the outline for the program that has succeeded so well for the Frisa Forjados - Superalloys Plan. In the past year, the operation has completed a Job Hazard Analysis on all new and modified operations, as well as the plants lockout/tagout (LOTO) visual aids. As well, it has implemented daily inspection checklist procedures for cranes and hoists, and forklift trucks. The plant’s next goal is to achieve a DART score of 0.48.

Considering his own plant’s progress, Augusto Ponce said, “First, it is our experience that if you have good leaders who are really committed to safety, the results can be extraordinary. My advice is, ‘focus on developing these values in your leaders and managers.’

“Second,” he continued, “try to involve the workforce on the decision making process of what needs to be addressed. Most of our solutions for safety issues have come from them, usually with high impact and low cost.”

Every Worker, Every Day

The FIA Safety Award winner among the largest plants (over 325 employees) is Scot Forge Co.’s Spring Grove, IL, operation, which produces open-die forgings and rolled rings up to 80,000 lb., and custom forgings in numerous shapes and sizes.Our safety mission statement is simple,” according to John P. McGillivray, Safety & Environmental manager there. “Every employee-owner goes home today without an injury.”

The challenge to achieving this, he noted, is “preventing complacency from taking someone’s focus off what they are doing, which results in them ending up in the line of fire or somehow losing their balance, traction, or grip.”

At the core of Scot Forge’s safety efforts is the combination of a behavior-based safety observation process with awareness improvement training, using Electro-Lab’s SafeStart program. “It is an extremely effective combination that has helped dramatically reduce our injuries and builds employee engagement and buy-in,” McGillivray said.

Recently, Spring Grove added to the effort with a “6S program” (5S with an added component for safety, he said), which has improved housekeeping standards and brought greater organization to work areas.

Scot Forge also tracks leading indicators to remain aware of safe working conditions. Each employee is expected to complete four observations per month, and the ‘safe percentage’ as well as the number of observations is tracked. Also, a number of the observation cards address near-miss situations, and McGillivray noted that shop employees do a good job to analyze those events and suggest ways to prevent them occurring again.

Job-specific safety training at Scot Forge is done by a method described as “Walk Me Through It,” both for production processes and maintenance work orders.

“Employees are asked to describe the hazards of the task they are about to do to the observer,” he detailed, “and the risk reduction measures they are taking to eliminate or minimize those hazards.

“Then, the observer steps back and observes the employee performing the task to ensure that the employee utilizes the risk reduction measures. This approach is a great learning tool because if the observer is more experienced than the employee performing the task, he can use it as a teaching/training opportunity,” McGillivray said.

Working safely is an expectation, he continued, so Scot Forge develops processes and procedures that employees are trained to recognize and practice, “so that each of them has the best opportunity to go home at the end of their shift uninjured.

“We recognize individual, department, and plant milestones for safe work performance,” the safety manager said. “That recognition creates a sense of pride in people and they want to continually improve their personal and department’s performance.”

He added the importance of “safety” at all times, at home and off the job, are emphasized too. “To us, the impact of an employee being injured, regardless of where it happens, has a negative impact on the injured individual, his/her family, and to our company, in that order of importance.” As a result, Scot Forge workers are encouraged to extend the safety message to their family members.

In addition to the observation process and awareness training, Scot Forge employees are encouraged to be subject matter experts, to develop the training procedures, and to provide the training. Each month, hourly employees perform numerous safety audits.

The results in the past year have been apparent. Spring Grove had three areas of emphasis for its safety program, starting with a thorough revamp of new-hire training to instill safety and job-skill proficiency more effectively, and efficiently. It also undertook a complete update to LOTO procedures and NFPA 70-E training, and it institute training for all employees in the SafeStart principles.

The next objectives are to continue updating existing safety processes, and to refine further the observation, audit, and awareness training methods.

McGillivray said that other forgers wishing to emulate Scot Forge’s award-winning standard should focus on setting high expectations for workers’ safety performance, and on working “relentlessly” to achieve that through short-term goal setting.

“What must be done to get through this next task safely?” he said. “That’s your focus. Tasks where no one is injured add up to shifts where no one was injured, which lead to days where no one is injured, and so on.

“For companies in our industry to stay competitive, long-term, in a global economy, we need to maximize our resources available, to reinvest in our people and equipment,” McGillivray advised. “One way of doing that is stopping preventable injuries. Scot Forge has reduced its OSHA total incident rate from 25 in 1997 to a projected 0.5 for 2014. Safety makes good business sense and good safety performance is achievable with the correct focus and expectations.”