Universal Stainless & Alloy Products Inc. has gained Nadcap Heat Treat accreditation at its radial-forging plant in North Jackson, OH. The same plant gained the Nadcap Materials Testing Laboratory (MTL) accreditation last September. Also, the company’s Bridgeville, PA, plant achieved the Nadcap Materials Testing Laboratory (MTL) accreditation in December 2012.

Universal Stainless manufactures stainless steel, tool steel and other alloyed steels, which it supplies as semi-finished and finished products to aerospace and defense manufacturers. Included among its products are forging billets, but the North Jackson plant that it acquired in 2011 for a reported $104.5 million as a nearly finished project has made it a forging producer, too.

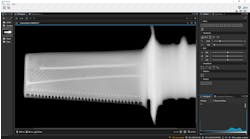

It produces large and long forged squares, rounds, bars, and custom shapes for aerospace, power-generation, petrochemical, and general industrial tool steel and shafting applications.

After the purchase in 2011 the buyer completed the construction and the radial forge that is a core element of the operation started up in the second half of 2012.

In addition to the radial forge (described as "the largest hydraulic radial forge in the Western Hemisphere"), the 200,000-sq.ft. plant near Youngstown, OH, includes a vacuum induction melting (VIM) operation, two vacuum arc remelt (VAR) furnaces, an electro-slag remelt furnace, heat-treating operations, and various long-products finishing equipment.

Nadcap is the National Aerospace and Defense Contractors Accreditation Program, which certifies critical production processes and testing standards for compliance with quality control and safety standards. It’s a cooperative program that unites the major aerospace and defense manufacturers and their suppliers, and is designed to manage a cost-effective consensus for special processes and products and to provide continual improvement.

The North Jackson plant was successful at meeting all of requirements of Nadcap’s checklist AC7102 — the general requirement for all Nadcap-accredited heat-treating operations.

"Achieving the Nadcap Heat Treat certification is a further step in our plan to expand our penetration of growing markets," stated Universal Stainless’ Chris Zimmer, vice president of Sales and Marketing. "We are very proud of this latest accomplishment in North Jackson. It underscores our commitment to serve the demanding international aerospace market."