Latest from Quality Control

New Article

AI-Powered, HD 3D Scanning

Quality Management Software Release

How to Track Maintenance Costs

X-Ray Inspection Made Easy

Pyrometer Series Extended

High-Speed IR Camera

Multifunctional Thermal Flowmeter

Back on Track with Oil Analysis

ADCOLE CORP.’s upgraded camshaft measuring machine is engineered to handle longer camshafts for large diesel engines, and provides submicron. The Model 911 camshaft gauge for diesel engines handles parts up to 105 in. long and features a video monitor to ensure the center hole is lined up and engaged. It employs a footswitch-operated opening and closing function for the tailstock.

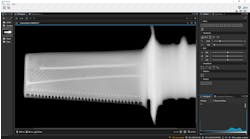

Capable of automatically measuring 360° around the part, including all cam lobes, reference journals, timing features, and keyways, this gage provides submicron accuracy and can detect material buildup and other irregularities.

Featuring precision carriageways to ensure ±0.25 micron radial accuracy, the Model 911 measures each cam lobe’s axial profile from edge to edge and creates a 3D image that illustrates the shape and identifies irregularities. According to the developer, the gage has become the world standard for milling and grinding machine tool users to ensure there is product conformance for suppliers and OEMs.

Visit www.adcole.com