You can buy individual bolts at the hardware store for less than the price of coffee, but that is no indication of the value of that such an item may bring to a structure or system. "Fasteners" — the term that design engineers use — refers more clearly to the functional value of such items, but both terms glide past the importance of hot and cold forming in their production.

An excellent example of the value is seen in the range of applications reported by Swedish manufacturer Bumax AB, which has supplies stainless steel fasteners for demanding applications in some high-profile engineering projects. The latest of this is the European Southern Observatory Extremely Large Telescope (ESO ELT), a $1.2-billion project to build the world's largest telescope in the Atacama desert, in northern Chile, by 2024.

The ELT will be a reflector telescope, collecting "universal light" using a 39-meter wide, curved mirror to gather 13 times more light than the largest optical telescopes existing today. It will be able to correct for the atmospheric distortions, providing images 16 times sharper than those supplied by the Hubble Space Telescope. Its developers claim it will vastly advance astrophysical knowledge by allowing detailed studies of planets around other stars, the first galaxies in the universe, super-massive black holes, and of the universe's dark sector.

Such an expansive structure is much too large to be made from a single piece of glass: It will consist of 798 individual hexagonal segments, each measuring 1.4 meters across and carefully positioned by electrical motors. These segments will work in coordinate as a single mirror to collect 100 million times more light than the human eye.

Each one of these 798 mirror segments, plus 133 additional segments (designed to ensure continuous interchange as mirrors are cleaned and recoated) will be affixed with 12 fasteners — 10-mm long, Bumax 109 M6 bolts.

“Standard stainless steel bolts lack the strength required for the ELT,” stated Michael Evers, project manager at VDL ETG, the Dutch engineering group that is developing the ELT. “We required a 10.9 strength bolt, and with the corrosion resistance of stainless steel."

He added: “The high-strength Bumax 109 fasteners prevent damage to the mirror segments, which is very costly. Their corrosion resistance is also essential as the fasteners are sometimes open to the elements and will reduce future maintenance requirements.”

The Bumax organization traces its origins to the Åshammar Forging & Nail foundry established in 1660, which became Åshammar Bolt Factory in 1899. It has been producing austenitic stainless steel fasteners since 1926. Now, it develops and manufactures stainless fasteners under the Bumax brand, available in a range of stainless steel materials for various demanding applications.

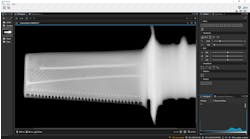

Fasteners are cold forged at the plant in Åshammar. Cold forging, in which finished and treated stainless bar stock is die-formed, usually followed by rolling and heading for proper dimensional control, "gives a superior product with increased strength and improved fatigue resistance," according to Bumax. All of its products are delivered with full traceability and 3.1 certificate, and the Åshammar operation is certified according ISO 9001 and 14001 standards.

Other recent, high-precision applications for Bumax 109 bolts have included stainless steel studs, nuts, and washers for two 219-MW North Sea wind turbines; and the zero-point clamping system developed by AMF for CNC milling and turning machines, to ensure fast and precise fixture and workpiece changes.

The manufacturer's fasteners are also to be found on the CERN large Hadron collider in Switzerland, various satellites, submarines, and numerous installations where reliable and precise mechanical structures are expected.

Commenting on the ESO ELT telescope project, Bumax managing director Patrik Lundström Törnquist called it, “another testament to Bumax being able to provide the very best fasteners for the most demanding applications.”