Manufacturers everywhere think their operation has one-of-a-kind problems achieving process efficiency or product quality, and every technology supplier strives to customize its proposals to those manufacturers’ concerns. But, in fact, there are broad trends driving manufacturing technology — process automation, energy management, and resource optimization, just to list a few. In regard to industrial heating, the trend is “continuity.”

TimkenSteel will start up a new quench-and-temper line next year. The $40-million project combines induction preheating and heating furnaces to austenitize and temper 4- to 13-in. bars and tubes at a rate of 50,000 tons/year. The design aims to impart specific levels of mechanical strength to various steel grades and products. The process will start with heating of the steel bar or tube to a uniform temperature in a walking-hearth furnaces, usually over 1,500°F. This will be followed by quenching in a hot liquid (usually oil or water), or air, depending on the grade. The second step will achieve the rapid cooling that will impart material hardness.

TimkenSteel and its development partner, SMS Meer, rightly consider the design to be unique, and yet it fits within the trend of heating processes closely integrated to larger production sequences.

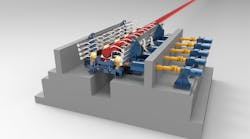

SMS is developing another installation for a German steelmaker, Deutsche Edelstahlwerke, in which steel bars up to 250 mm diameter will be heat-treated directly in the rolling line. By eliminating a separate heat-treating step the producer will save production time and energy costs, as well as storage and handling requirements, and significantly increase its potential for higher volume throughput.

Heat treating will be integrated into the material flow of the existing mill. Individual bars will be transported on a roller table to an equalizing furnace. Depending on quality demands, this process may be adjusted for different grades of structural steel or tool steel. After heating, the bars will be cooled selectively to the desired temperature, according to a customized simulation model.

Temperature equalization will take place in a walking-beam furnace designed for energy efficiency and temperature uniformity (over the length and cross-section), as well as low emissions. Level 2 controls for furnace heating zones will optimize furnace efficiency, calculating and maintaining the bars’ thermal profile.

According to the developer, the new line will make it possible for the producer to set and maintain tighter process parameters. This may include not only measurable qualities, like the steel grain size range, but also reduced inherent stress and greater product homogeneity. “The surface quality will improve measurably, also allowing more precise testing,” according to SMS, which emphasized the new process will be tailored to individual customers’ requirements.

The new line will be commissioned at the end of next year