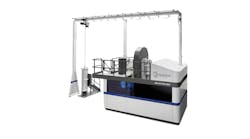

Inductoheat Inc. reports it designed, built, and recently shipped a two-module induction billet-heating system to an unnamed forging company, to feed a 4,000-lb. board hammer. This InductoForge

® machine was designed specifically to heat 1-2.5-in. diameter billets to 2,450°F.

InductoForge is line of modular billet-heating systems that Inductoheat supplies for forgers to match heating capability to production capacity by assembling appropriately sized (500Hz - 6000Hz) induction power modules. The system includes a heavy-duty, single-size forging coil consisting of cast end boards, copper windings and long-life removable liner for heating a wide range of billet diameters and shapes.

Billet heating is controlled by the IHAZ™ Temperature Profile Modeling computer program for advanced control of the process. IHAZ

™ allows operators to customize a billet temperature profile (Induction Heat-Affected Zone) to suit their billet or bar heating application.

In the recent installation, the forging line starts with a 6,500 lbs capacity automatic bin tipper that allows a bin of 1- to 2.5-in. diameter carbon steel billets, 10-22 long, to be dumped into a vibratory bowl feeder with automatic refill. The billet bowl feeder provides continuous feeding of billets, end-to-end on a pinch wheel in-feed system for precise control.

Once in the single-size induction heating coil, the billets are accurately heated to 2,450ºF at a nominal rate of 250 pieces per hour. Process control is enhanced by IHAZ

™ software, which enables advanced temperature control of the billet heating process. In addition to controlling billet temperature, IHAZ

™ can generate the optimal running parameters and set points for Standby and Rapid Start, which are stored as a recipe in the billet heater's AB Compact Logix PLC and AB PanelView 700+ controller.

After the billets are heated to the target temperature profile, they exit the induction coil on a fast-extractor conveyor, while the infrared temperature pyrometer activates the over-and-under, accept/reject system.