Welding and maintaining tooling for forging operations has always been a challenge. Today, one of the greater obstacles facing forging operations is the ability to find and keep good, hands-on welders who have not only the necessary skills (or, at least are willing to learn) but who also can endure the high heat and physical stress required to perform the job of tool-and-die welding on a daily basis.

According to recent studies, today’s younger workers are seeking more “high tech” positions, in contrast to hands-on professions that require training in manual skills. In particular, this describes positions such as welding.

The American Welding Society predicts a shortage of more the 375,000 welders by the year 2023. Now, more than ever, genuine help is needed for those companies straining to meet growing demand for their products while maintaining their forging dies and components.

Robotic welding has been in industrial use for several decades and it has helped considerably to help manufacturers in need of welding services, in various capacities. But, until recent years there has never been a successful, automated robotic die welder. The project to invent an automated robotic welding system started in 2006, initiated by Luca Giamberini and Andrea Tonoli who are affiliated with DG Weld, an Italian firm active in die maintenance and repair. Drawing from their years of experience with manual welding, and recognizing the lack of skilled and experienced welders, Giamberini and Tonoli foresaw an automated die-welding system and started to collect data to use in that development.

Robots were the logical approach for their vision, but manually programming robots is time-consuming, useful only for simple shapes, and not very economical. So, Giamberini and Tonoli developed and patented the missing part of the equation: dedicated offline programming software to be used to program robots quickly and accurately for each unique welding job.

Eureka Welding Alloys, with nearly 100 years of tool-and-die welding activity, recognized the same growing need for die-welding and -repair, and had developed a solid working partnership with DG Weld.

Eureka Welding Alloys worked with DG Weld to develop a line of robotic welding wires that have run with great success in these systems worldwide over the past five years. To date there are over 30 automated robotic-welding systems operating efficiently in over a dozen countries. Combining our resources, we have an established a proven, revolutionary advance to the future of tool-and-die welding.

Preferred methods — Until recently the preferred method for die and component repair was flood welding, and to date this is still widely applied and highly successful. While flood welding has been the industry standard for die and component repair for decades, there are costs associated with the time needed to complete flood-welding repairs as well as the material costs for wire/electrode consumption. One of the goals of the new automated system is to reduce the cost of welding by cutting down weld times, as well as to reduce the amount of product used in each project.

Consistency and repeatability from the robotic welding process produces further benefits that increase productivity by reducing machining times as well as tooling costs; as less weld material is put into the workpiece, there is less material that will have to be machined out of it to complete the repair.

The automated system usually consists of a two-person team, a programmer and an operator, each with separate but important responsibilities. The programmer, of course, takes care of programming the job, using the dedicated offline software, a critical component developed by DG Weld.

The operator takes care to run the welding jobs generated by the programming software with the robot.

It is important to note that the programmer and operator work together, as each has a particular perspective on the projects. It is essential that both share what they see and hear throughout the process. Working together, both of them benefit from their collaboration, and this will result in a more productive work environment.

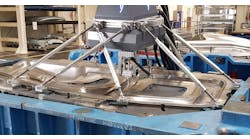

System hardware and set-up — The hardware needed for the automated system consists of a six-axis robot with a robot controller, ranging in size and working envelope from small to medium, to large. The system uses a pulse-arc welding power source, and this along with a 0.062-mm (1/16 in.) diameter welding wire allows it to deposit weld beads at lower voltage and amperage, reducing the heat-stress input to the workpiece and weld deposit, and eliminating the need for peening after extinguishing the arc.

All systems are equipped with enclosures and safety systems, including door sensors, emergency stop buttons, and a control panel. Optional items that may be equipped are self-cleaning torch stations, electrically heated welding tables, and servo track systems for larger installations.

There are two conventional methods used to prepare a die or component for welding: carbon arc gouging and machining. Carbon arc gouging is the quicker and more economical approach, but due to its nature it does not produce the same prepared geometry every time, like machining does. The quality of the gouge is largely dependent on the skill of the operator, and the result will vary in quality between operators.

Because of this, a laser scanning arm of some type is needed to obtain that prepared geometry of the die or component for programming the welding job. If the die or component is prepared for welding by machining, the geometry of that machined prepared die or component will have a CAD file that can be used for programming.

Another benefit of a pre-machined impression is that no laser scanning is needed; it is cleaner and 100% repeatable.

With robotic welding a 3D laser scanner is a valuable tool to have available. Besides using it to obtain the geometry of the gouged die or component, it can be used to check if enough material has been removed. The gouged model can be overlaid to the finished machine model, and then sections can be sliced. Then, the programmer can check the difference between the two models to see how much stock material was removed.

The laser scanner can be used again after the welding job is done to check the final welding deposit thickness for accuracy, using the color-mapping function of the scanning software. It will present the low and high spots on the welded die or component in a range of different colors. This information can be used to optimize the program to improve future welding jobs of the same die or component. For example, if too little or too much weld is being applied consistently, the welding program for the die or component can be modified to address this issue.

Programming, post-processing, and welding — Once the workpiece is prepared for welding, either by gouging or machining, and the geometry has been obtained, the programming can begin. The programmer will need to import and align the models and input a series of parameters that the software needs to generate the target mesh or welded geometry and the weld path calculations.

Once the weld-path calculations have been generated, they must be translated into robot movements. The software is equipped with a virtual cell, where the geometry of the robot with welding torch and welding table has been created. The weld-path calculations are translated into robot movements, and lines of code are generated that the robot controller can read. In this portion of the software the entire welding program can be run, and the programmer can check for proper workpiece placement, torch collision, singularity in the robot joints, etc.

This part of the process is referred to as post-processing. If an error occurs during post-processing the software will let the programmer know at what line of code it happened, and the programmer can go into the software and fix the error in the virtual cell, rather than risk it reoccurring in real time, and thereby decreasing the likelihood of a collision that may damage the welding torch or robot. Once post-processing has been completed and the welding job has been confirmed to have no errors, it is ready to be uploaded to robot controller by the robot operator.

Before welding can begin the operator is responsible for the following steps:

1.) Uploading welding programs;

2.) Workpiece alignment;

3.) Dry-run beginning of weld program.

Along with these details the operator is responsible for general maintenance of the welding robot and weld area. While welding is being done the operator is responsible for checking for proper weld deposition. Are the weld deposits tying in the walls properly? If not, a parallel shift can be applied to move the weld program on the X, Y, or Z axes. Is the weld program building up each layer at a consistent rate? If the weld deposit is not building up at a consistent rate on each layer, the weld job may not deposit enough weld material and will not reach the before-mentioned target mesh or welded geometry, resulting in low spots after machining is done.

Conversely, if the weld is building up too quickly the weld job will result in excess weld material being deposited. This issue can be checked and resolved in several different ways.

A few more of the operator’s responsibilities are more common in die welding. Needle scaling after each layer, wire changes and contact tip substitution, as well as replacing other consumables that may wear out. The operator is responsible for checking for proper gas flow, that the correct shielding gas is being used, correct welding wire is being used, and that hand tools are good working order.

If all the parameters, steps and procedures are followed the automated robotic welding system will result in continued, successful welding jobs for years, ultimately resulting in higher-quality weld deposits due to a consistent wire stick-out and better controlled fluctuation in voltage and amperages. Rather than flood welding the entire impression, the system contours the shape of the die geometry, resulting in less material being put into a workpiece and less material needed to be removed in the machining process.

The automated system is user friendly and training can be done in just a matter of one to two weeks. One operator can comfortably run up to three systems at the same time. Robotically welded dies are yielding better results, with die life improved by as much as 20-30% due to the advancement of specifically designed robotic wire.

Luca Giamberini and Andrea Tonoli are affiliated with DG Weld, a developer of repair and restoration processes for forging dies and tools. Chris Kerchkof is the sale manager for DG Weld's North American partner, Eureka Welding Alloys. Learn more at www.eurekaweldingalloys.com, or contact Chris Kerchkof at [email protected]