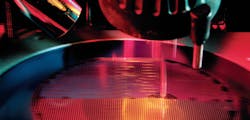

Prevent Fab Failures Before They Start

Reliable linear motion is an absolute operational necessity in a semiconductor fab. From a prevention standpoint, semiconductor manufacturing machinery OEMs must monitor even relatively rare failure risks in linear motion components or systems throughout design and manufacturing.

The stakes are enormous, with failure of a single part or system costing a fab hundreds of thousands of dollars for even a relatively short-duration downtime event—or even more depending on location, severity, and response time for repair or replacement.

The 3,000-word report details how to specify, design, and install next-generation linear motion systems in semiconductor manufacturing machinery used in metrology, wire or die-bonding, wafer dicing and scribing, and packaging.