Semiconductor Industry ZL Pressure Transducers and HPT Gauge

The ZL91 and ZL92 Pressure Transducers and HPT Gauge are for the semiconductor industry. The fluoropolymer construction makes them compatible with processes that use corrosive or non-contaminating fluids. In non-contaminating processes, their wetted parts prevent metal ion elution – perfect for ultrapure or deionized water processes.

The 63mm HPT anti-corrosion pressure gauge features fluoropolymer wetted parts. It is fabricated in a class 10,000 clean room and then nitrogen flushed and packaged into a polyethylene-sealed bag. You can use it in chemical delivery systems, wafer manufacturing, ultrapure water applications, plating processing, and within the pharmaceutical industry. Using a PFA Bellow material, it has a span accuracy of ±1.5% (ranges 90 psi and above) or ±2.0% (ranges 90 psi and below).

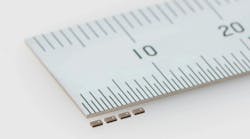

The ZL91 and ZL92 pressure transducers are high-quality additions to our semiconductor product line. The ZL91 is designed for use in ultrapure/deionized water applications that require all-fluorine resin wetted parts and low metal ion elution in their process. The ZL92 is designed for use in semiconductor processes that require fluoropolymer wetted parts for improved chemical compatibility with acids and other corrosive fluids. Each model provides a full span accuracy of ±1.0% and is ideal for semiconductor, flat panel displays, water facilities, and wet stations.

HPT Gauge

- PTFE/PFA Wetted Parts

- 100% Nitrogen leak tested

- Class 10,000 cleanroom packed and bagged

ZL91 Transducer

- PTFE/PFA wetted parts

- Low metal ion elution

- Compatible with pipe diameters from 0.25 to 1.0 in. O.D.

- Capacitance sensor for excellent thermal stability

- Multiple mounting options include tube connections, press fit nuts, flared nuts and threaded nuts

- Class 100 cleanroom packaged and double bagged

- Designed for low and negative pressure measurement

- IP65 ingress rating

ZL92 Transducer

- PTFE/PFA wetted parts

- Corrosion resistant to chemicals such as hydrofluoric acid

- Low metal ion elution

- Compatible with pipe diameters from 0.25 to 0.5 in. O.D.

- Capacitance sensor for excellent thermal stability

- Multiple mounting options include tube connections, press fit nuts, flared nuts and threaded nuts

- Class 100 cleanroom packaged and double bagged