Venturi Desuperheaters

Sept. 3, 2021

Related To:

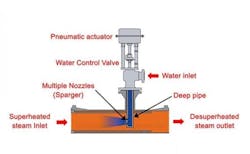

Venturi Desuperheaters reduce steam temperature by bringing superheated steam into direct contact with water, eliminating the need for heavy insulation of steam lines. They reduce the temperature of vapors flowing in a pipeline by heat transfer through evaporation. Liquid injected at the throat of the Venturi is atomized into small droplets by high vapor velocity. Superheated vapor is cooled by evaporation of the droplets as they flow downstream.

A major feature of this desuperheater is that it obtains a stable conditioned desuperheated steam flow temperature that handles a high amount of cooling water injection in the shortest time possible.

Venturi Desuperheaters are used mainly in chemical plants and refineries.

- Protect critical equipment in process plants against heat distortion

- End product deterioration by superheated vapors

- Eliminate need for heavy insulation of steam lines

- Reduce expensive, heat-resistant alloys in process equipment

- Lower superheated steam temperature for use in operating auxiliary equipment