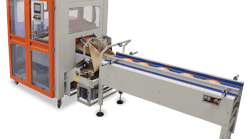

Affordable Shrink Wrapping System

The TLS Series L-Sealers now come with upgraded Allen-Bradley controls and a standard HMI touchscreen interface, making them the ideal sealing machines for customers who are looking for easy operation, minimized labor and maximized efficiency.

The TLS Series L-Sealer shrink wrapping systems are made for customers who are seeing an uptick in business, but their existing packaging processes have limited automation. The TLS Series represents an entry-level machine to help automate customers’ packaging capabilities by increasing throughput while reducing labor within their production line. It has been engineered to be a workhorse for companies as it can operate continuously for three shifts a day, seven days a week.

The TLS Series L-Sealers simultaneously make the end and side seal of one package, as well as the front seal of the trailing package. The seal is made by feeding product into the centerfold film with photo-eyes detecting the leading and trailing edge of the product. The TLS Series L-Sealers feature Texwrap’s patented Motion Trim Technology. The benefit this technology brings to customers is that it increases throughput by running infeed and exit conveyors at a speed of up to 100 feet per minute while seal jaws are in motion – making it the fastest, most durable L sealer on the market.

Features and benefits:

- Clean corner cut tail removal: Cleanly cuts film tail by squaring the package prior to sealing, resulting in consistently strong seals and superior aesthetics

- Programmable multi-pack feature: Automatically collates and wraps single lane multi-packs

- Pass-through feature: Standard option to allow product to move through machine without shrink wrapping the product

- Auto reversing belt: Reversing feature relaxes film to create better seals and reduces film usage, especially with tall products

- 10-year warranty

- Maximum package size: 10.5” height x 19.5” width x 32” length

- Minimum package size (with closing conveyor): 2” length x 2.75” width

- Film width

- Maximum: 28” center folded

- Minimum 6” center folded

- Optional 64” folded attachment with 32” unwind

- Conveyor speed: 20 to 100 feet per minute

- Air requirements: 80 PSI, 4 CFM

- Electrical requirements: 240 VAC, 1-phase (480 VAC optional)

- Construction: heavy-duty welded tubular steel standard (corrosion resistant optional)