Flying Motion Control With XPlanar

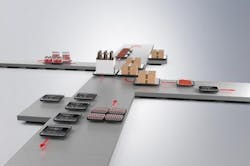

Unlocking entirely new possibilities in machine design, the XPlanar system features flying motion control where planar movers float freely above planar tiles arranged in customizable layouts and enable flexible, precise, and highly dynamic positioning.

XPlanar comprises a base of freely arranged planar motor tiles, which measure 9.4 x 9.4 in. (240 x 240 mm) and can be arranged in any desired geometries that are adapted to the application at hand. The tiles generate electromagnetic fields to levitate and propel passive movers in multiple sizes through integrated permanent magnets. With speeds up to 6.5 ft/s (2 m/s) and max acceleration of 1 g, movers carry payloads ranging from 0.88 to 9.2 lb. (0.4 to 4.2 kg) and can work together for even larger payloads. The movers can be used not only horizontally, but also vertically and even upside down.

Path planning, automatic collision avoidance, 360-deg. rotation and anti-sloshing functionality are standard in the motor tiles and TwinCAT software. As such, XPlanar delivers unlimited customization, fully integrated functionality, and simplified programming for diverse packaging machines.

The innovative system offers advanced capabilities for adaptive packaging, material handling, and inspection, along with opportunities to shatter conventional thinking in automation, implement non-linear processes, and enable true lot-size-1 production. The Flying Motion system creates no contamination through contact-free and wear-free movement, and the freedom to use any surface covering—stainless steel, glass, plastic, etc.—makes XPlanar a sanitary, washdown-capable solution.