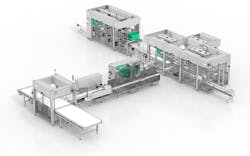

Seamless Paper Packaging System

A high-speed seamless system for bars, including all steps from process technology up to case packing, the WRW Flex compression roller allows manufacturers to adjust the height and width of their bar mass slabs during production with maximum flexibility and precision. This minimizes trim, thus eliminating product waste. Once the bars are cut and fanned out, they are fed into the Sigpack HRM flow wrapper by the contactless, format-flexible, and compact Sigpack FIT infeed with XTS linear motor technology. The HRM features the new paper-ON-form retrofit kit in combination with cold sealing technology—the first of its kind to process paper packaging without compromising on speed and product safety.

The seamless system comes with the proven Sigpack TTM top load cartoner. The gentle feeding module Sigpack FWV makes sure that the paper flow wrap’s sensitive barrier layer remains intact, even at maximum speeds. This is a major quality benefit throughout the overall packaging process. Additionally, the Sigpack TTM processes cardboard made from 95% recycled fibers with utmost precision. In the final step, the Elematic 2001 packs the cartons into cases. The case packer stands out for its efficient use of packaging materials, including slightly bent blanks as well as grass fiber corrugated board. The machine can handle up to 100 different case designs with a speed of up to 40 cases per minute.