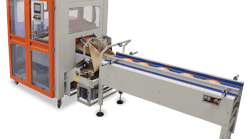

Vertical Wrapping System

The Texwrap 914BVS Continuous Motion Orbital Vertical Wrapping System is designed for lower speed vertical applications. The BVS series has a capacity of 60 to 70 packs per minute. In addition to in-line applications, it is perfect for contract packagers where the products are often manually loaded to form variety or multipacks.

Texwrap vertical wrappers use a full bottom trim seal instead of a lap seal to securely enclose the product. In addition to providing an outstanding seal, this eliminates the unsightly seam across the side panel of the package common with other machines. Often used with printed film to eliminate the use of carrier trays or "boots", the precise product and film control of the 914BVS allows smooth, consistent operation with precise print registration.

The reduction of maintenance requirements is an important part of the design of every Texwrap wrapper. These systems use “Generation 3” servo technology meaning that it was designed from the ground up to integrate servo technology, PLC control, and the mechanical elements of the machine. The result is a fast, reliable, and flexible wrapper with minimal moving parts, minimal maintenance requirements, and maximum performance.

In addition to a variety of custom infeeds, Texwrap also offers a product orientation system as an option for the 914BVS. Using servo-driven wheels, the orienting head grips the groups of products and spins them to a predetermined position so that the labels are precisely aligned making a very attractive and functional multipack.

- Welded, heavy-duty powder-painted construction

- Large product size capacity (914BVS 8"W max, 14"H max)

- Film capacity: 48" SW or 24" CF

- Low mount film unwind for easy loading

- Servo sealing mechanism (2-axis)

- Texwrap's exclusive Versa Seal bottom trim seal

- Independent conveyor control allows relaxed film at cross seal and transitions

- Centerline design

- Built-in flexibility; can be configured with many infeed types

- Swivel mounted touch screen with set-up helper product recipe memory and machine diagnostics

- Upstream/downstream handshaking, feeder controls, optional quick-connect cable system for additional equipment

- Internal scrap take up with an advanced oscillating guide, film break, take-up reel alarms, and quick release spool

- Allen Bradley controls

- Safety interlocked sliding doors for easy access