Orbital Stretch Wrapper

The H. BÖHL orbital stretch wrapper eliminates loose fill packaging material by providing superior load stability. The product is first placed on a suitable tray, with material type, size and weight determined by product, and placed inside the wrapper. The unique orbital design wraps the stretch film over and under the product, tightly securing it to the tray. After the product is placed in the outer box it is safely secured, minimizing or in some cases eliminating additional product protection or dunnage.

North American manufacturers are discovering the Bohl is an ideal load stabilizing solution due to its intuitive design, high speeds, low material cost, maximum uptime, low noise operation, minimal setup times, and ability to link together with automated production lines.

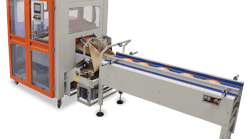

When coupled with the Little David Case Sealer SP-304, the tray packing system delivers optimized results. Engineered for a range of uniform cases and industrial environments, it reduces labor costs associated with manual case sealing. Its automated three flap folder, with universal bottom flap folding bars, provides fast and uniform closure while automated taping seals the box. Equipped with interchangeable tape cartridges and top squeezer rollers, the Little David Case Sealer SP-304 features an automated CaseLocker ST tape cartridge that requires no lubrication and helps avoid the twisting motions known to cause carpal tunnel syndrome. The tape cartridge’s knife guard system means that workers are not exposed to the blade as it is only exposed when the rollers have been depressed.