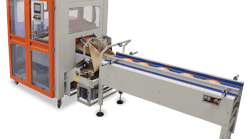

Streatch Wrap Machine

Signode, a leading manufacturer of a broad spectrum of consumables, tools, software and equipment to optimize end-of-line packaging operations and protect product in transit, is highlighting two of its unique solutions for the corrugating industry at CorrExpo 2019 in Denver, CO. Divided in two exhibit spaces, Signode booth #300 features stretch wrapping technologies for greater unitized pallet loads and booth #301 showcases high-speed bundling solutions.

For those looking to unitize corrugated pallet loads, Signode introduced its Octopus™ Twin Series automatic rotary ring stretch wrapper to the corrugated industry. Able to wrap up to 150 loads per hour, the Octopus™ Twin features the classic ring-type method of wrapping coupled with a unique dual film carriage design. Its robust construction and well-balanced design maximizes efficiency and reliability.

The machine’s ring design allows for unlimited wrap patterns due to its ability to begin and end film cycles at any vertical point on the load. This inherent feature increases flexibility and reduces film usage up to 25%. With dual film carriages, the Octopus™ Twin further reduces film roll changes by 50%, significantly increasing labor savings, uptime and overall machine efficiencies. In addition, the wrapper utilizes an “s” style film carriage. When compared to traditional wrap systems, the “s” wrap pattern improves pre-stretch levels, can better handle a variety of films, and significantly lowers the overall cost of ownership.

This highly intuitive machine is also easy to operate and install. Loaded with benefits, the Octopus™ Twin Series can accommodate variable load sizes and features multiple machine options to meet varying packaging challenges.