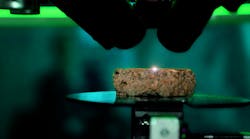

High-End Metal Analyzer

SPECTRO Analytical Instruments introduces the SPECTROLAB S high-performance arc/spark optical emission spectrometry (OES) analyzer for the analysis of metal in process control and research applications. The analyzer represents a real revolution in high-end OES metal analysis — featuring SPECTRO’s proprietary CMOS+T technology and delivering the fastest measurements, lowest limits of detection, longest uptime, and most future-proof flexibility in its class.

Many users of high-end stationary metal analyzers are tasked with identifying and measuring — with exceptionally high accuracy and precision — all the elements and compounds in their incoming, in-production, and outgoing materials. This may also include research on new materials. The new SPECTROLAB S is designed to be the best-performing spectrometer available for primary metal producers — as well as an equally excellent solution for secondary metal producers; automotive and aerospace manufacturers; and makers of finished and semi-finished goods, electronics, semiconductors, and other end products.

In terms of sample throughput, SPECTROLAB S meets the metal market’s need for ultra-high-speed measurement. Example: when analyzing low alloy steel, it can deliver highly accurate measurements in less than 20 seconds.

The SPECTROLAB S has the world’s first CMOS-based detector system that’s perfected for high-end metal analysis — thanks to SPECTRO’s proprietary CMOS+T technology. From trace elements to multi-matrix applications, it provides high-speed, highly accurate analysis plus the lowest limits of detection in its class — limits previously attainable only with PMT detectors. On some key elements, SPECTROLAB S CMOS+T technology surpasses PMT performance.

Uptime is outstanding. SPECTROLAB’s regular maintenance intervention requirements (spark stand cleaning) have been reduced by a factor of eight.

Calibration is easy and cost-efficient, needing only a single-sample, 5-minute standardization. In most cases, unique iCAL 2.0 diagnostics ensure stable performance from then on — regardless of most shifts in ambient temperature or pressure. Most users save at least 30 minutes a day.

The analyzer’s flexibility ensures that it is future proof. New elements or matrices can be added via a simple software update — eliminating the need for substantial hardware modifications.

SPECTRO’s familiar, intuitive user interface ensures effortless ease-of-use — even for less experienced personnel. Instead of multiple dialog boxes, a simplified operator view presents clear choices via dedicated toolbar buttons. Tailored application profiles eliminate complicated method development.

The SPECTROLAB S provides both short-term and long-term stability. Unlike conventional analyzers, its sealed, no-purge optical system maximizes light transmission stability, even in the far UV. Its software utilizes sophisticated measures such as online drift correction and iCAL 2.0 temperature compensation for reproducible readings, even over successive shifts or maintenance intervals.

To fit packed laboratory spaces, the SPECTROLAB S features a 27% decrease in footprint over previous models. Conveniences include an easy-reach start/stop button and fixed function keys; a spark indicator light; noise minimization construction; and quick, tool-free access for spark cleaning or air filter changes without opening the main instrument housing.

SPECTRO helps ensure uninterrupted performance and maximum ROI life via unmatched AMECARE services. Machine-to-machine (M2M) support allows proactive alerts, backed up by an on-request PC connection with a remote SPECTRO service expert.