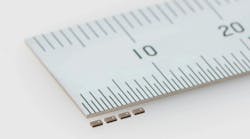

Lead-Free Fuse Thwarts Dendrites

Expanding the MGA range of 1206 SMD ceramic fuses is a COTS+ version for aviation applications. The MGA-A is completely lead-free, while protecting against the formation of tin whiskers and dendrites.

Crystalline tin dendrites and tin whiskers pose a considerable risk of short circuits in highly dense electronics. Dendrites form during the electro-deposition process whereby heavy marks could appear on the fuse end caps or housing. A thorough inspection and cleaning is required according to MIL-PRF 23419. Tin whiskers on the other hand form after the electro-deposition process. The cause is not well understood, although adding lead to otherwise pure tin soldering is commonly used as a preventable measure.

The natural element of lead, however, has become known as a toxic element. As such, it is mostly eliminated from soldering through the implementation of environmental initiatives, e.g. RoHS directives. The MGA-A uses gold alternatively to lead. Gold plated end caps provide a surface where neither whiskers nor dendrites can form. The technical design of the MGA-A is essentially the same as the MGA COTS version and the MGA-S, which is the version up-screened for European Space Agency (ESA) qualification and ESCC listing. With its ultra-robust thin-film construction, hermetic seal, and operating temperature range of -55 to +125°C, the MGA-A is a safe solution for use in not only highly sensitive electronics in the aviation industry, but also in widespread industrial-grade applications including intrinsically safe applications according to ATEX and IECEx requirements.

The MGA-A is cURus approved for 0.2 to 5 A, with a particularly high breaking capacity of up to 300 A at 125 VDC for currents up to 3A; 32 VDC for 4 and 5 A versions. Humidity and moisture tested to MIL STD 202. Shock and vibration tested to IEC 60068-2.

- No tin whiskers, no tin dendrites

- No leaded coating (RoHS conform)

- Similar fuse qualification as in MIL-PRF 23419

- Hermetically sealed and robust construction