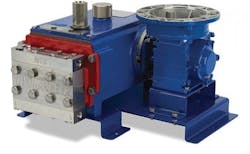

Low Flow/High Pressure Metering Pump

Hydra-Cell Metering Solutions model MT8 triplex metering pump is designed to handle a variety of processing fluids at low flow rates and high pressures. It features a multiple-diaphragm design to provide virtually pulse-free flow without the need for pulsation dampeners. The MT8 pump exceeds API 675 performance standards for steady-state accuracy (±1%), linearity (±3%) and repeatability (±3%), the company states.

Flow capacity for the MT8 ranges from a minimum of 0.06 gph (0.227 lph) to a maximum of 8.0 gph (30.28 lph) with discharge pressure ratings up to 3500 psi (241 bar) depending on flow. The integral relief valve protects the pump from over pressurization on the discharge side. The replenishment valve system in every piston ensures optimum actuating oil on every stroke for continuous accuracy and protects the pump from damage in the event of a blocked suction. Electronic flow control increases accuracy and reliability while hydraulically-actuated diaphragms provide superior performance across the entire pressure range.

Chemical processing applications include oil and gas (onshore and offshore), water and wastewater treatment, chemical injection, polyurethane foam, and other uses including pharmaceutical, power generation, personal care products, and additive injection for a variety of plastics processing applications.

The MT8 triplex metering pump features the Hydra-Cell seal-less design, so there are no mechanical or dynamic seals, cups, or packing to leak, wear, or replace. Current models are available in 316L Stainless Steel, Alloy 20, Hastelloy C, PVC, and PVDF pump head materials options, Wanner Engineering says.

Featuring rugged construction and a small footprint, one MT8 pump covers a wide range of flows and pressures, which reduces inventory requirements and provides for fast, simple field conversion. To install a complete metering system, a variety of options and accessories are available from Wanner such as motors, valves, calibration cylinders, and the exclusive Hydra-Cell Metering Solutions Control FreakTM touch-screen metering controller.

| Diaphragms per Liquid End | 3 |

| Flow Control | Electronic variable speed drive |

| Maximum Discharge Pressure | |

| Metallic Heads: | 3500 psi (241 bar) |

| Non-metallic Heads: | 350 psi (24 bar) |

| Maximum Inlet Pressure | 500 psi (34 bar) |

| Non-metallic Heads: | 300 psi (20 bar) |

| Operating Temperatures (min./max.) | |

| Metallic Heads: | 40° to 250°F |

| Non-metallic Heads: | 40° to 140°F |

| Consult factory for temperatures outside this range | |

| Inlet Port | 1/4 in NPT or BSPT |

| Discharge Port | 1/4 in NPT or BSPT |

| Maximum Solids Size | 200 microns |

| Oil Capacity | 1.75 US quarts (1.7 liters) |

| Weight (less motor) | |

| Metallic Heads: | 100 lb. (45 kg) |

| Non-metallic Heads: | 75 lb. (34 kg) |