Hardy HI 1734-WS POINT I/O weight processing modules were recently deployed to economically replace older analog strain gage conditioners used to measure force on a pipe extrusion machine. Immediately, the HI 1734-WS modules dramatically reduced calibration and set-up time versus the older analog strain gage conditioners.

With 96 channels of strain-gage inputs per machine, each with course and fine adjustment trim pots, hundreds of manual ‘tweeks’ were required using a small screw driver and steady hands to dial in the process. “By the time we are done with fine-adjustments on the 96th sensor, the first needed to be adjusted again”. Using the C2 weightless calibration of the HI 1734-WS modules, what used to be an almost perpetual process can now be done with a software command; calibration is automatically preformed at the click of a button. Likewise, the HI 1734-WS can also re-zero the equipment after drift occurs instead of arduously making manual adjustments with a screwdriver.

A second benefit is increased product quality and product consistency. Replacing the 16-bit analog input modules with Hardy’s 24-bit digital solution not only improved resolution of the process by a factor of 200X, but the process also benefited from Hardy’s advanced digital filtering technique called WAVERSAVER that virtually eliminates electrical noise and mechanical vibrations inherent to the equipment. The noise and vibrations were the source of constant erroneous readings back to the control system – causing the process to hunt for adjustments that weren’t necessary and ultimately caused deviations in pipe wall thickness. With greater resolution and the elimination of erroneous readings – wall thickness can now be controlled (using the same mechanics) to a level never seen before on the equipment.

The HI 1734-WS is a true weight processing module designed for POINT I/O systems, as opposed to passing raw A/D counts through to the PLC for interpretation as in competitive models. It is also easy to configure using a Rockwell Automation Add-On-Profile (AOP) and an easy-to-use Faceplate.

The HI 1734-WS is ideal for applications where fast, stable weight data and low cost of ownership are important. It is designed to be a high-performance replacement for analog transmitters with the advantages of noise filtering and vastly superior scale settling times. It is ultra-compact, reducing machine cost and control cabinet footprint. The module also includes Hardy Process Toolbox features: C2 weightless calibration, Integrated TechnicianTM system diagnostics, and WAVERSAVER immunity from mechanical vibration.

Features:

- Easy to mount, set-up, calibrate and maintain

- Rockwell’s Adaptor Products allow connectivity to EtherNet/IP, DeviceNet, and ControlNet in linear, star and ring topologies

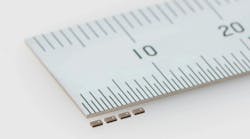

- Ultra-compact at just a ½ in. wide, the HI 1734-WS module saves cabinet space over the use of dedicated instrumentation, reducing both machine cost and control cabinet footprint

- Up to 8 350 ? per weight processing module

- Consumes just one watt when powering a Hardy IT junction boxes and up to 4 load cells

- A Rockwell Add on Profile (AOP) and Faceplate with Add-on-Instructions (AOIs) makes it easy to integrate the HI 1734-WS into the manufacturing process control applications of a Rockwell controller with no programming required.

- Features Hardy Process Toolbox features including C2® weightless calibration, Integrated Technician™ Diagnostics and WAVERSAVER® mechanical noise supression