New Version of VERICUT at IMTS

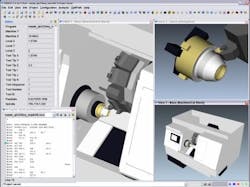

“The result of this work is a tightly unified environment for simulating complex mill/turn multi-function machining centers for production processes,” said Product Marketing Manager Bill Hasenjaeger.

VERICUT 6.0 leverages the results of simulating these complex processes with the ability to create inspection instructions, CNC inspection programs, and automated process documentation using the simulated workpiece. Because of VERICUT’s accurate feature-rich in-process model of the simulated workpiece, the inspection and process documents utilize and accurately reflect the state of the workpiece at any stage of the process.

To ensure VERICUT’s simulation is as accurate as possible, CGTech has partnered with many key machine tool builders, control manufactures and CAD/CAM companies. CGTech’s Technology Partner Program establishes a cooperative working relationship with a goal of helping mutual manufacturing customers maximize their success and productivity.

“IMTS is a fantastic show for us because not only do we get a chance to meet with many current and future customers, we can meet with most of our partners under one roof. No other show is that productive,” said Hasenjaeger.

VERICUT runs under Windows and UNIX operating systems. Headquartered in Irvine, California CGTech specializes in numerical control (NC/CNC) simulation, verification, optimization, and analysis software technology for manufacturing. Since 1988 CGTech’s product, VERICUT® software, has become the industry standard for simulating CNC machining in order to detect errors, potential collisions, or areas of inefficiency. VERICUT enables NC programmers to reduce prove-outs, virtually eliminate errors, and optimize NC programs for faster, more efficient machining. With offices worldwide, VERICUT software is used by companies of all sizes, universities/trade schools, and government agencies.

CGTech, VERICUT, and OptiPath are registered trademarks of CGTech.

AUTO-DIFF and X-Caliper are trademarks of CGTech.