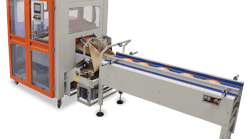

Lantech's new Q-300XT stretch wrapping machine improves life for fork-truck drivers with a larger load-placement window for its automatic film cut-and-clamp system. Designed to eliminate fork-driver dismounts, the patented XT film cut-and-clamp system now allows a generous 10-inch offset for most loads, while providing automatic attachment of the film to the load and cutting of the film upon completion of the wrap cycle. The newly engineered XT module has one-third fewer parts than the previous generation, along with a larger linear bearing, lighter-weight components for reduced inertia and impact, and a new hinged design that flips up for easy cleaning of the mechanism. The fully guarded cut/clamp system also grabs more film at the end of wrapping for improved unitizing reliability. The new XT module is standard on all Q-300XT and S-300 XT stretch wrappers starting in August, and a retrofit kit for existing machines with the XT cut and clamp module will be available for select models. The Q-300XT stretch wrapper allows the fork truck operator to simply drive up, position the pallet on the turntable, start the machine with a lanyard switch, and drive away - without ever getting off the fork truck. Simple Automation* of the Q-300XT reduces wear and tear on fork truck operators and equipment. The higher efficiency can free up fork trucks for other uses or possibly eliminate some equipment and the associated operating costs. The Q-300XT wraps 30-40 loads per hour, up to 80" (2 m) tall and weighing up to 4000 lb (1814 kg). The machine's electronically controlled, variable wrap force and 200% pre-stretch on the film ensure consistent, tight loads with economical use of film, reduced labor and improved ergonomics. Film pre-stretch up to 300% is available as an option. The stretch wrapper is easy to operate with a touch panel control, featuring color-coded operating functions for quick, clear identification. And, the entire system is backed by a full three-year, unlimited-cycle, all-component warranty. Lantech's packaging and productivity solutions include semiautomatic and automatic stretch wrapping; automatic case handling; automatic palletizing; shrink packaging and pallet-load conveying systems. Lantech is the originator of stretch wrapping technology and world's largest manufacturer, with 55,000 systems placed around the world. Headquartered in Louisville, Kentucky, with manufacturing operations in the U.S. and the Netherlands, Lantech products are sold and serviced by a network of 175 distributor locations. Visit the Lantech website at www.lantech.com for more product information.