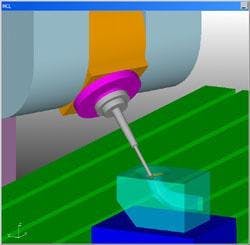

NCCS, the developer of NCL multi-axis machining software for the aerospace, automotive and turbo machinery industry, announces the new release of the latest version of NCL 9.5 that improves productivity by reducing both programming time and cycle time. Among the dozens of time saving enhancements included in NCL V9.5 are the following new capabilities: Roughing strategies for large components: Tactics have been added to reduce machine cycle time by allowing the user to specify machining zones with the option to machine to final depth within each zone. The user controls the order in which zones are machined and the order in which regions within each zone are machined; Multi-axis roughing: New strategies have been added that allow 5-axis rough machining of non-prismatic components. The ability to access undercut and contoured areas results in reduced machine time and a consistent material allowance for subsequent finishing operations; Quick profiles: A new interface allows multi-axis contouring of a series of surfaces with a few clicks of the mouse. Automatic profiling of 3D curves, with multi-axis tool control, has also been added to support complex engraving operations and to provide additional ease and flexibility for general profile operations. David Schultz, NCCS’ Manager of CAD/CAM Applications says “Overall, NCL V9.5 raises the bar to a new level offering time-saving enhancements by enabling users to quickly generate profiles of 3D curves, with more tool control, additional ease and flexibility”.