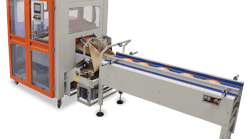

Lantech's revolutionary RS-6000 20-second stretch wrapping system meets the needs of consumer product companies shipping high volumes of pallet loads, providing the highest capacity in the industry at 180-200 loads per hour. A "first" in the packaging industry, the new RS-6000 Ring-Straddle™ design introduces a unique and patent-pending film delivery system capable of wrapping loads with 50-ga. film, pre-stretched 250% or more – without film breaks. According to Lantech, the new pre-stretch head and speed wrap get film onto the load so quickly that almost all film recovery (the film trying to "un-stretch" itself) occurs on the load, resulting in high containment force and reduced film use.Developed to the specifications of a leading consumer goods manufacturer, the RS-6000 automatic conveyorized stretch wrapping system enables OEM's to satisfy mass merchandisers who want more SKU's in their warehouses, wider brand selection on their shelves and faster turnover of smaller inventories. "The new requirement from big retailers is 40-inch load height, not 70-inch, so the same volume of product has to ship on twice as many pallets," explains William Caudill, Lantech's marketing manager for automatic stretch wrapping products. "Suppliers want to minimize floor space and capital equipment with a single high-speed stretch wrapper that can match the 20-second cycle time of today's fastest palletizers, and the RS-6000 has been developed for this specific requirement." He adds that all suppliers to the large retailers are being affected, including household chemicals, food, drugs, cosmetics and beverages. The RS-6000 Ring-Straddle™ stretch wrapper can wrap loads up to 50" x 50" x 80" (LWH). Starting and ending the wrap cycle is a new cut-and-clamp system that combines a new heat-free Press 'n Seal film sealing system. "A cut/clamp/seal cycle takes 4-5 seconds with a typical system, but this new patent-pending system gets it down to about 1.5 seconds to reduce our total cycle time," Caudill says.Standard on the RS-6000 is Lantech's patented Pallet-Grip® system for locking a load to a pallet. Pallet-Grip effectively attaches a load to the pallet with bottom wraps of film that have been twisted into a cable along the lower 4-6 inches of the web. This tightly wound film cable is wrapped with 50% higher wrap force as it is secured an inch or two below the deck of the pallet, while the remaining film web stays above the deck and secures the load. Pallet-Grip wrapping leaves the fork-truck through holes open, ensuring that wrap force is never weakened. The new film delivery system can wrap the complete pallet all the way to floor level without a load lift, saving $10-15,000 per machine. The new system also allows loads to be wrapped with as little as two pounds force. "Light loads are a problem for an electrically powered pre-stretch system, because the load always has to pull on the film to keep the system in dispensing mode. This machine can put a dust cover on a pallet of uncased paper towels, without deforming the load, twisting it, or crushing product on the corners," he says. Clever design eliminates all overhead maintenance items that might require a ladder or man-lift. Pre-wired at the factory, the new design also allows the machine to ship in a single closed truck with its standard three sections of conveyor. It can be set up in one day, compared to three days normally needed for a typical overhead stretch-wrapping machine. The control system for the machine is based on an Allen Bradley CompactLogix PLC and PanelView Plus color touch screen.According to Caudill, the RS-6000 breaks through a sound barrier of sorts that has limited stretch wrappers to a maximum speed of 50 rpm. "Above 50 rpm, the forces on the machine structure spike off the chart, but more importantly the response time of an electrically powered pre-stretch system cannot match the acceleration and deceleration needed to go faster," he explains. "The structural issues were overcome with good mechanical engineering and finite element analysis. However, the film delivery system required a new approach that mechanically links film payout to the movement of the head on the support ring." A standard electrically powered film pre-stretch system has to first sense a "demand" for film, then it gradually ramps up output as it continues to sense "pull" on the film, he explains. It also has to decelerate in a gradual way at the end of the wrap cycle. "This lag in response time adds to the overall cycle because the film delivery system needs one revolution to reach peak output, and one revolution to decelerate," says Caudill. "Our new film delivery system has no ramp-up delay. It instantly pays out film in direct proportion to its speed of movement on the ring. This allows it to accelerate to 60 rpm from a dead stop without breaking the film. An electronic system cannot do this."