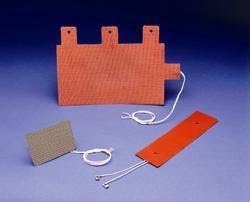

The particular application conditions of aerospace, medical, composite fabrication, optical equipment and computers often require flexible heating elements. Durex offers a wide assortment of in-stock and custom flexible heaters in Kapton® and silicone rubber materials to suit most any of these needs. Kapton® flexible heaters offer superior tensile strength and tear resistance, with precision heat distribution. They are also ideal for applications with extreme temperature environments, -319°F to 392°F (-195°C to 200°C). Heaters in stock standard at 0.007” (0.2 mm) thick and up to 20” x 26” (.508 m x .660 m) area. Watt density is 5W/in2 (0.8W/cm2 ) standard. Silicone Rubber heaters permit composite bonding and curing, as well as repair and fabrication operations. Equal length circuits and a cool tab are provided, while a fiberglass reinforced heater cover means long service life and increased durability. Standard watt density is 5W/in2 (0.8W/cm2). All standard heaters are UL Recognized. Many sizes in stock from 6” x 6” to 20” x 20” (152.4 mm x 152.4 mm to .508 m x .508 m). All Durex flexible heaters are available with custom design modifications. Specification: • Sizes: up to 16” x 29” • Standard Thickness: .007“ in •Maximum Watt Density: 50 W/in² (depending on application) • Standard Maximum Resistance Density: 100 ohms/in² • Standard Dimensional Tolerances: Less than 12” ± .062 , Greater than 12” ± .125 • Maximum Operating Temperature: 500°F (260°C) • Minimum Operating Temperature: -319?F (-195?C) • Wattage Tolerance: ±10% • Dielectric Strength: 1000 VAC