The Flo-Check USB Hydraulic System Analyzer simultaneously measures flow, pressure, temperature, and power within a hydraulic system. Data is received from the analyzer through a standard USB cable and is displayed and logged through a custom Windows-based software application (both software and cable are included).

The unit is bi-directional and includes a low-resistance load valve and internal pressure relief discs. The analyzer can be used as a stationary or portable tester and is ideal for testing, troubleshooting, and diagnosing service issues for any piece of hydraulic equipment, such as front-end loaders, cranes, and excavators, and for setting hydraulic components including pumps, valves, and motors. It features flow, pressure, and temperature sensors that are monitored by a data acquisition module.

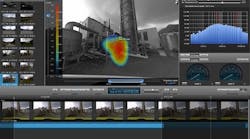

This module records the operating parameters of the system and transfers them to the user’s laptop via the USB port. Powered through the USB connection, the Flo-Check is easy to set up and ideal for portable applications. Interfaced with the PC application, the device offers a straightforward method of monitoring system parameters complete with data acquisition. It can be set for continuous measurement, controlled start/stop measurement, or up to 12 hours of continuous logging. In addition to displaying and logging data in a real-time graphical measurement, the customized software that accompanies the analyzer offers several value-added features, such as the ability to set alarms. With three sets of high/low alarm indicators monitoring flow, pressure, and temperature, a user is able to set defined parameters for hydraulic system operation. If the high or low alarm point is breached, a visual alarm indicator is triggered and the incident is logged in a data file.

Furthermore, the device works well for measuring hydraulic system efficiency over time. When conducting regular system maintenance, the Flo-Check can be used to log a baseline performance reading. Over time, this information can identify any trends toward a potential system failure and allow for corrective action before experiencing a more costly breakdown and repair. All data is saved as a .csv, or comma-separated value file, making it simple to export into most spreadsheet programs.