IIoT Tool Demonstrates Benefits of Digitized Pneumatics

Helping pneumatic system users quickly and easily see the potential benefits of integrating IIoT, the Smart Pneumatics Analyzer can be connected to the compressed air supply on an existing machine to show users instant analysis options for key machine characteristics such as compressed air consumption and possible leakages.

The portable analyzer case contains a Smart Pneumatics Monitor, AS series air preparation units, and a tablet for visualizing the live data. Emerson personnel can show a user within minutes how they can use IIoT-enabled data for insights into their own machine.

The monitor initially detects the system operating state, analyzes data, and provides this processed information to users for status-oriented maintenance, for example. While other solutions collect all available data and transfer it unfiltered, the monitor evaluates the data locally and uses it to generate information about the status of the system. All data from the valves, as well as from components connected to the I/O modules on the valve system, is read into a microprocessor and processed by means of mathematical algorithms. These algorithms are based on decades of expertise in AVENTICS pneumatic product engineering and application.

Condition monitoring, the collection of operating states and their prediction as the basis for anticipatory maintenance, offers direct advantages for customers using IIoT applications. Because they can anticipate wear before it leads to machine downtimes, they allow users to significantly increase the availability of their equipment and reduce maintenance costs. Once defined limits are reached, the electronics can automatically send messages to ERP and MES systems, as well as maintenance or other staff. Data collected can also help optimize pneumatic systems’ energy efficiency.

Features:

- Local preparation of data (edge computing)

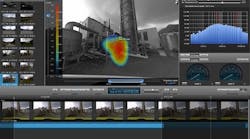

- Local visualization of sensor data

- No additional software required (web browser)

- Measurement without overriding the PLC-controlled process

- Portable, can be used on different machines

- Includes all functions to start with IIoT

- Visualization of live and historical data

- Demo mode with random data for demonstrations without air

- CSV Excel export of all sensor data

- Leakage detection by pressure drop test

- Electrically operated valve controllable via dashboard

- Time synchronization

- Visual comparison of consumption data from various measurement intervals