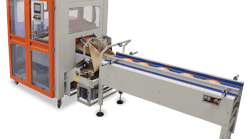

GaleWrap, an ITW Corporation company, introduces the improved 87” Standard Manual Model Yellow Jacket 110® Orbital Stretch Wrap Machine for securing any standard, oversized or odd-shaped palletized loads right on the forks of the forklift. The loads are wrapped and secured as a horizontally positioned stretch-wrap dispenser moves around and under a load as the Yellow Jacket 110 is manually advanced across the length of the load. The improved 87” diameter model has increased capacity and speed, offers a “beefier” design, is more convenient and easy to use than previous models, and provides for simpler maintenance. The 87” Manual Yellow Jacket 110 offers the following user benefits: Delivers increased “wrapped load” capacity and speed: • The upright supports have been turned and moved out for full ring use, increasing the overall load size capacity • Direct drive motor increases ring speed (how quickly the stretch-wrap dispenser moves around the load) Has a “beefier” design: • The width is increased for additional stability (overall footprint is 114” wide x 92” long x 98” high) • The bolted, mainframe connections have been replaced with welded connections to reduce vibration and increase strength, durability Other “beefier design” improvements include a heavier/sturdier rail system, heavier duty bearings and a solid bar replacing the “pan” design of the cross members for increased strength. Lexan on the unit’s side and front increase visibility and safety. Convenient, easier to use: • Casters of previous models are replaced by fork pockets to increase stability and provide a safer, easier way to move the unit • The unit does not require a pallet to ship and the lower height eliminates the need for oversize trucks and dock doors. Frame offers protection during handling and shipping • The handlebar was moved to the left side for increased visibility and convenience for the forklift driver Easy maintenance and retrofits: • New gear system’s lubricant is filled at the factory and requires no maintenance • The unit can be modified in the field by adding semi-auto or fully automatic parts (retrofit kits) • New maintenance points allow for easier access for maintenance and inspection ITW-GaleWrap markets GaleWrap® Oriented Film and Oriented Equipment as an alternative to conventional hand wrapping. GaleWrap Oriented Film and Equipment offer increased wrapping productivity, enhanced employee safety, improved load containment and lower total pallet wrapping costs. • Maximum Load Capacity: • 68 1/8" • Maximum Wrapping Length: • 77" • Machine Dimensions: • 91" x 93" x 95" • Power Requirements: • 110-volt Ring Speed: • 5 - 20 RPM • Controls: • Push Button • Film Type: • Standard 20” Machine Grade Stretch-Film • Film Delivery: • Core Brake w/ Adjustable Tension • Portability: • Fork-Lift Portable