NEW WAX EMULSION DELIVERS HIGH GLOSS AND CORROSION PROTECTION

March 14, 2008

Related To: Heatbath Corp

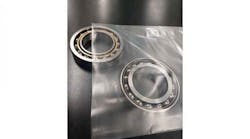

Heatbath Corp. has expanded its line of rust preventative products with the introduction of Durawax, a multi-purpose synthetic wax emulsion that provides excellent coverage over bare steel, or conversion coatings including black oxide and phosphates. Durawax forms a hard, shiny dry film that enhances surface appearance and durability. Applied over black oxide at 50% by volume, it delivers more than 400 hours of corrosion protection when subject to 100% relative humidity (ASTM D2247.) It can also be used as a dry film lubricant for torque reduction and other purposes. It is an excellent emulsion for the weatherproofing of military implements. Durawax is non-flammable, is used at ambient temperature, and dilutes with tap water up to 50% by volume. The bath is stable, and easy to replenish. Parts should be free of oils and residues, but pre-drying parts before processing is not required. Application is by spray, or immersion for 1-3 minutes. Films air-dry quickly, but forced air or spin drying can be used for in-process and other applications requiring faster cure. If needed, Durawax film can be removed with a hot alkaline cleaner. Durawax is silicone-free.